Choose an office

Choose an office

Choose an office

Choose an office

Home > Our news

Research & Development

CTE Wind R&D and Consulting services are the first choice when it comes to foundation design regardless of the WTG-manufacturer, model, size, power or soil conditions. Thanks to internal R&D-Team with senior engineers, holding over 100 years of cumulated experience in the design of wind turbine foundations, nothing is impossible.

La Richardais (FRA) – In 2019 Developers worldwide have globally commissioned a little over 45GW of onshore wind turbines. According to Bloomberg New Energy Finance, the Danish firm Vestas remained this way the world’s leading wind turbine supplier, with Spanish-German wind engineering company Siemens Gamesa a strong second. Chinas manufacturer number one Goldwind was third in the rankings, while US-Leader GE Renewable Energy’s secured its fourth place. Together the top four manufacturers accounted for 55 percent of the market share.

100 years of cumulated experience

This statement applies more or less also to CTE Wind, which calculated, designed and evaluated about 5000 WTG-foundations in 2019 around the globe. Thanks to CTE Wind’s internal R&D, with senior engineers holding over 100 years of cumulated experience in the design of wind turbine foundations worldwide, new turbine models from the top manufacturers as well as less common WTG-models from smaller or local manufacturers are only a little challenge. CTE Wind engineering services lead to state-of-the-art foundation solutions for wind turbines. Regardless of whether it is a prototype, such as GE’s giant 12 MW Haliade X or smaller 1 MW machine, from German ENO or Dutch EWT.

Wooden tower

Also worth mentioning: the different types of towers for wind turbines. Concrete (hollow foundation) and steel towers are well known to CTE Wind. Both tower systems are suitable to be used alone or in combination. Even foundations with wooden towers were calculated and designed by CTE Wind in the past. The sum of all experiences made during the projects since 2003 is the reason why their engineering services in foundation design are the first choice for wind turbine manufacturers, wind park developers and EPC contractors worldwide.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

According to Bloomberg New Energy Finance in 2019 developers worldwide have globally

commissioned a little over 45GW of onshore wind turbines. CTE Wind designed, valueengineered

or peer-reviewed foundations close to 1,500 WTG-foundations around the globe,

which represents around 5 GW of the installed onshore wind energy in 2019. A good result

for the 30 engineers working together worldwide. CTE Wind is an international engineering

consulting firm, headquartered in France, and specialized in the analysis and design of

onshore wind turbine foundations. Its engineering services lead to inventive foundation

solutions for wind turbines. In Rotterdam, they have designed the foundation for GE’s giant

12 MW Haliade X. But they are also with familiar with smaller 1 MW machines carried by

wooden towers. «Thanks to our experienced civil, structural and geotechnical senior

engineers the design of those wind turbine foundations worldwide are only a little challenge

to us», said Alexander MARTIN, CEO of CTE Wind International, «regardless if it is for new

turbine models from the top manufacturers or less common WTG-models from smaller or

local manufacturers», he added.

The sum of all experiences made since 2003 is the reason why CTE Wind’s engineering

team with offices in Brazil, Poland, Portugal, Spain, USA and Asia are often the first

choice for OEMS, wind park developers and EPC/BoP contractors. «That is how we

achieved to do over 17,500 wind turbines in 67 countries and without any failures», continues

MARTIN. One of CTE Winds main goals is to deliver foundation designs that optimizes the

use of resources and help to save concrete and reinforcement steel. Such a solution is the

patented SOFT-SPOT®, a gravity foundation with a soft layer under the anchor cage. Each

project receives an adapted design solution to the specific soil conditions. In Finland CTE

Wind designed a rock anchor solution when its engineers also designed a near-shore

foundation in Asias Mekong-Delta. «The trust of our customers leads us not only to

design special and new solutions but also the foundations for the biggest wind parks in

France, Spain and Poland. We are thrilled when we can play an important role in a wind farm

project. This shows the confidence of our customers in our designs and is also an

encouragement for us to continue to perform well», he ends.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

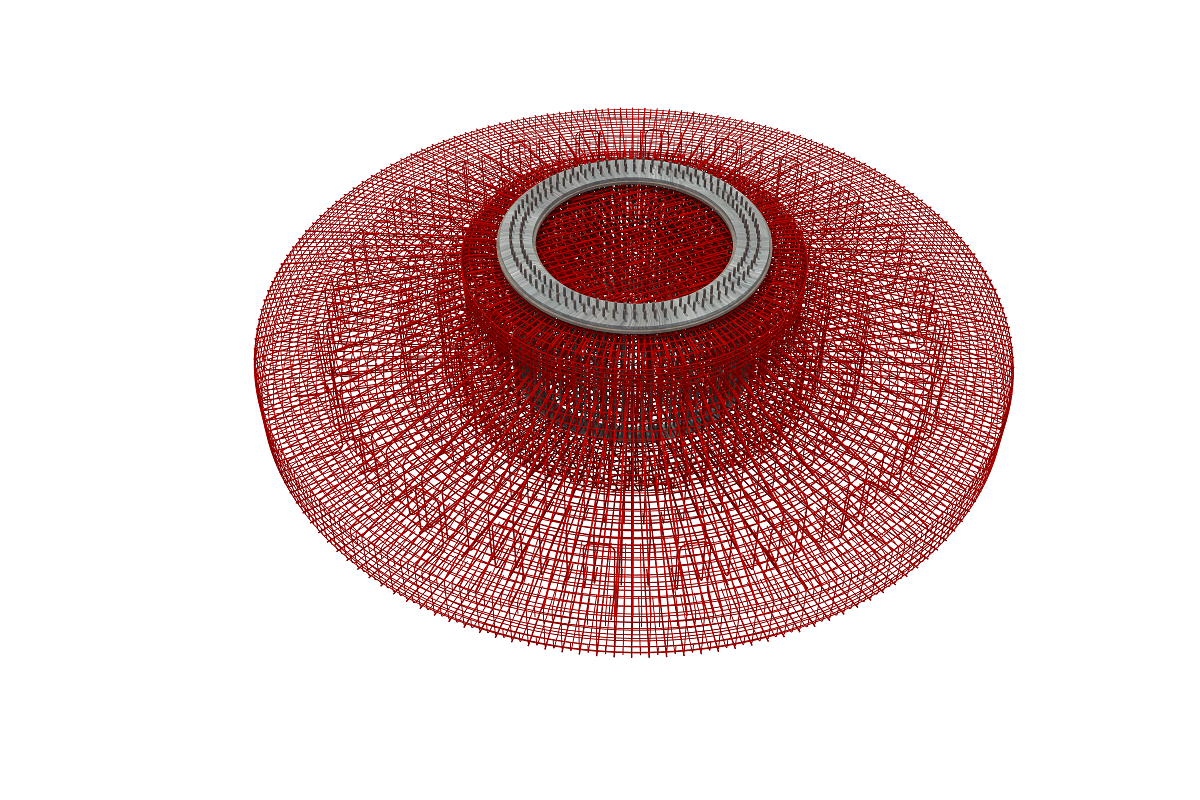

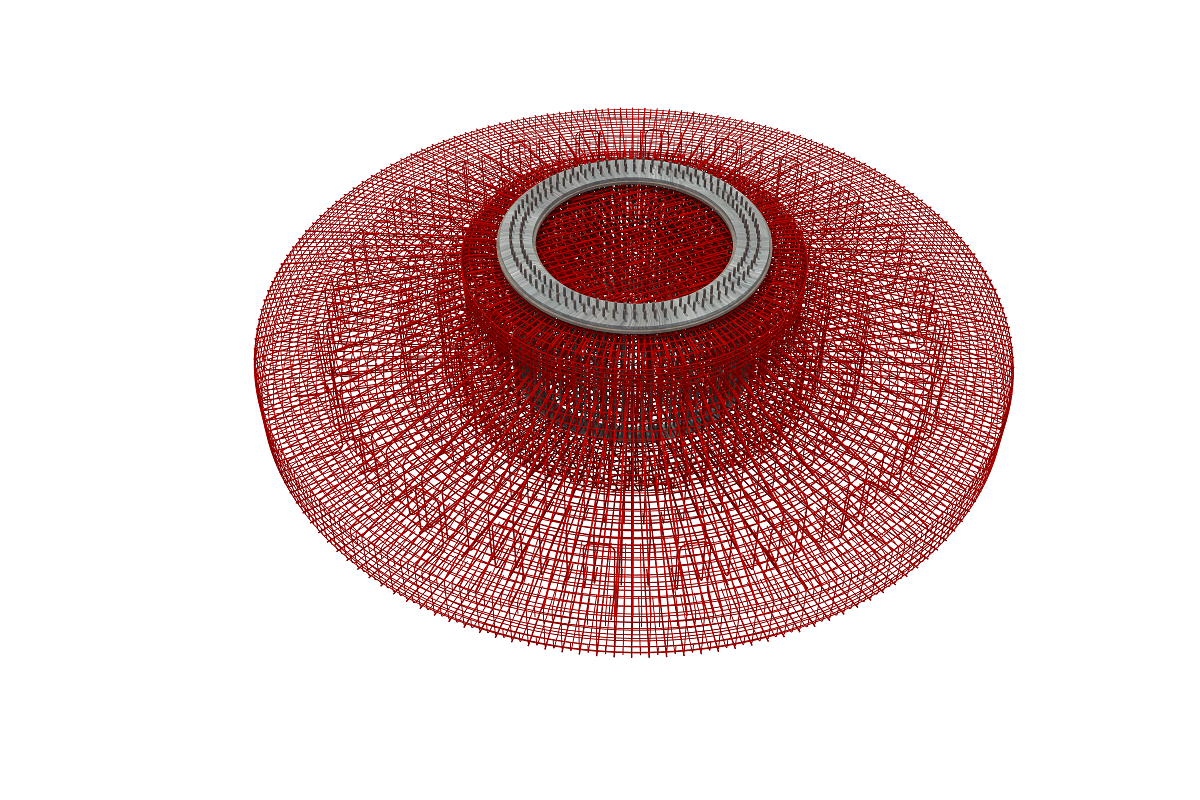

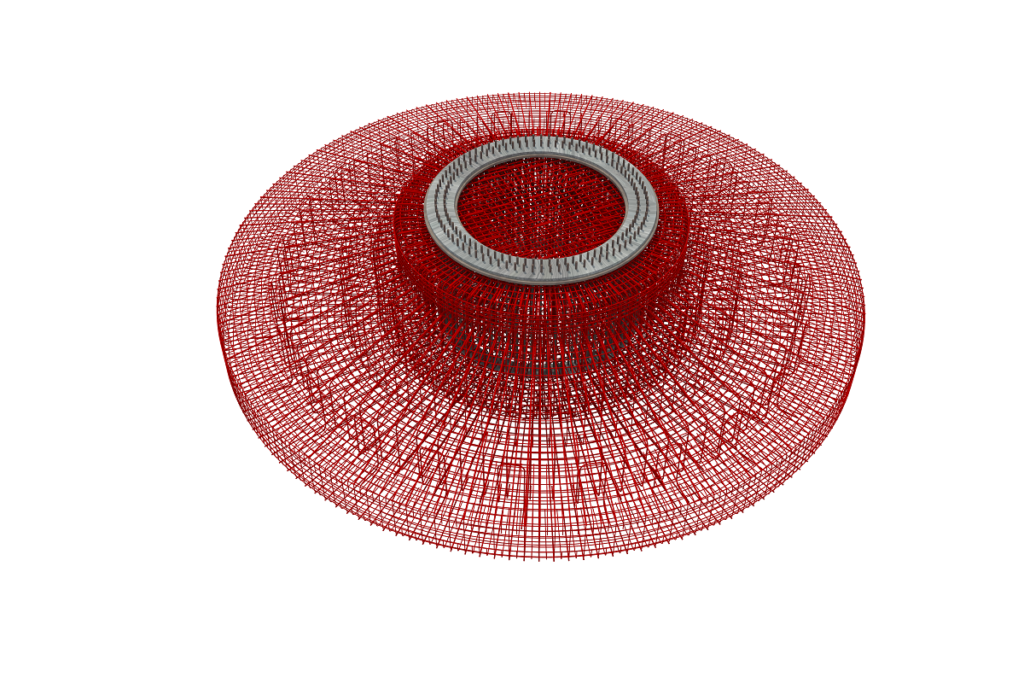

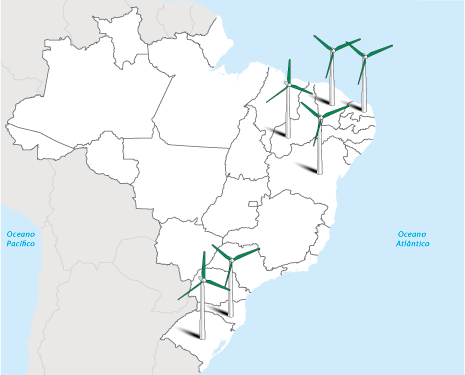

CTE Wind Brasil provides cost saving onshore foundations

Porto Alegre (BRA) – CTE WIND Brasil, part of CTE Wind International, has been active in the Brazilian market since 2005. After 2.5 GW installed wind turbine power or over 1000 designed, value-engineered or peer-reviewed foundations the next years highlight will be the consolidation of the patented Soft-Spot® solution in the Brazilian market. The result of the astonishing solution is the significant optimization of the bill of quantities compared to a standard gravity foundation: Savings in concrete, decrease of the foundation diameter (less earthwork) and total weight reduction of reinforcement bars.

The Soft-spot® is implemented in various countries around the world. Over 50 wind farms around the globe, 750 wind turbines are using this resource saving solution. Argentina, Chile, France, Lithuania, Indonesia, Mexico, Netherland, Russia, Serbia, Sweden Thailand and Brazil. With two new projects, one under development in the state of Bahia with 52 foundations scheduled for construction in early 2021, and an other already finished wind farm with 37 Vestas wind turbines V150 4.2MW in Rio Grande do Norte, things are on his best way to accomplish CTE Winds goals to be responsive, efficient and reliable worldwide.

To learn more about the patented Soft-Spot® solution please contact our Brazilian sales team in Porto Alegre or go and visite our Solutions section.

If you want to learn more about CTE Wind Brasil you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

Interview with Ana Bielza, Senior Engineer CTE Wind Iberica

Head of Geotech Services CTE Wind International

Since 2019 CTE Wind provides geotechnical engineering services to their clients. Over the last six months, Ana Bielza, Senior Engineer at CTE Wind Iberica has taken part in over 45 projects. We have asked her what she actually does and why her role is crucial for the foundation design of wind turbine generators (WTG).

Can you briefly explain to us what a specialist in geotechnical engineering like you does?

Ana Bielza: Geotechnicians apply scientific methods and engineering principles to predict the response of the ground to the foundation requirements. They then deliver this information to the civil engineers so they can design foundations accordingly.

What is the difference between common geotechnical engineering for bridges or building compared to the WTG-geotechnics?

Ana Bielza: There are not many differences. The ground has to be investigated with similar methods (drillings, geophysics, lab tests, etc.) and the same kind of parameters are needed. But the ground capacity is usually not what determines the foundation size, because most of the time the soil strength transmitted by a turbine foundation is not high. Besides, settlements in general are not important in this type of structures. But rotational stiffness can rather be the main ground parameter to manage and sometimes it can even set the foundation size.

CTE Wind offers his services worldwide

You worked on over 45 projects in six months, which is quite a lot. In which countries did you take a look at the ground?

Ana Bielza: Yes, there were many. It looks like our services are very appreciated by the customers (She smiles delighted). I worked for projects in Argentina, Australia, Belgium, Brazil, Chile, India, Indonesia, Israel, Lithuania, Mexico, Netherlands, Peru, Russia, Spain, Tanzania, Tonga, Turkey, and Ukraine. Of course, every country has its peculiarities. And I not only mean the different ground types you can find but also how the different investigations that are conducted and how the results are delivered.

Looking back on these last months, what were the challenges? Can you maybe share one or two projects with us?

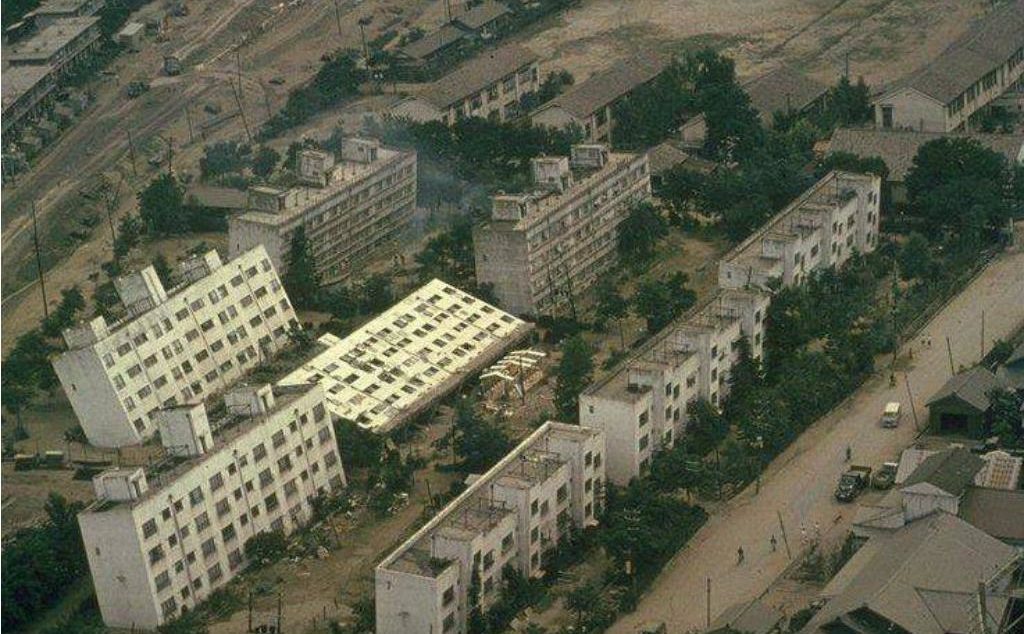

Ana Bielza: Challenging projects are usually the ones located on recent soils in seismic areas and near to the shore (high water table). For example, we have done several basic designs for a huge project in India with 1000 wind turbines, located on a saline desertic zone most of the year. But during the monsoon season the landscape becomes a swamp, with water at ground level. It is a region with an extreme seismic risks, on a recent granular soil (potentially liquefiable) and very aggressive to the concrete. We had to analyze the ground with just four boreholes in an area for 1000 turbines!

Sounds like fun. As far as we know, there are no known cases of significant damage from liquefaction in wind farms. So, how did you solve this problem?

Ana Bielza: Well, with only four drillings for such a huge area, it was mandatory to be conservative, therefore, and according to the client, we worked with two possible scenarios. We hope they were representative for the situation in most of the future turbine positions. The civil engineer then follows our specifications and designs the foundations accordingly with piles.

Trust is an important key factor

Could you tell us about another project?

Ana Bielza: Another challenging project has been the one in a country in South America, a wind farm with over 40 turbines. This was a constructive design where we had also drafted the geotechnical study from a factual report given by the customer, with 45 boreholes, 80 trial pits and 46 geophysical tests as well as an important amount of laboratory tests. The ground was good, a consolidated gravely soil -a conglomerate-, but seemed to be prone to suffer some dissolution because it had salt in its matrix.

What does it mean exactly?

Ana Bielza: The matrix describes the different layers a soil can have. The salt in the matrix can be dissolved by heavy rain or ground water. But even if the ground suffers an hypothetical dissolution, the remaining gravely soil would show enough strength and rigidity to carry the WTG. Besides, there was no water at all in the area, it was in a desert area.

Good conditions. What was the problem then?

Ana Bielza: Yes, but the client was pressuring us to set down categorically that there was no risk of dissolution, and there was no possibility at all for buoyancy. The geotechnics of the project showed good conditions for our SOFT-SPOT® foundation, but the wind farm owner seemed to have unfounded fears and wanted us to affirm that there was zero risk in this area. But zero risk does not exist. It was tricky to explain why there are no risk but we had to write about an hypothetical dissolution. Luckily, we finally came to an understanding. (ctewind)

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections.

For more Information about OUR-SERVICES please CONTACT US.

Rock anchor and high plinth foundations

.

.

Two simply but effective foundation solutions are the rock anchor, designed for a wind park in Mexico and the high plinth solution for a wind farm in Chile. They are highly cost efficient, feasible and have proven to be very reliable in many projects.

Bilbao (ESP) – Special requests often demand tailormade solutions. But tailormade needs an high specialization and a lot of knowhow from the engineers in the specific field. In foundation design for wind turbine generator (WTG), this specific knowledge is not that common, except for CTE Wind International. Their senior engineers are often asked to find new design solutions. For this purpose, they resort to tried and tested instead of reinventing the wheel. Two simply but effective solutions are the rock anchor and the high plinth solution. They aren’t NEW solutions but are highly cost efficient, feasible and their reliability has been proved in many projects. This article features two project cases, among many others, where CTE Wind International designed a rock anchor for a wind park in Mexico and a high plinth foundation for a wind farm in Chile.

Cost savings thanks to rock anchor

In Mexico CTE Wind Ibérica was selected as WTG foundation designer by a Spanish EPC company. The project has more than 20 WTGs with concrete towers. The project analysis conducted by the Spanish expert in foundation design has led to the recommendation to deploy two different solutions in order to optimize the costs of project. In fact, the soil conditions showed that over a third of the wind turbines were planned on rocky ground. Rather than equipping all wind turbine with standard slab foundations, CTE Wind’s engineering team decided together with the customer to implement rock anchors. This solution uses the rock masses as a WTG foundation. In that way the construction company is able take advantage of the earth crust instead of building a slab foundation. The costs for the reinforced concrete and the construction work can be saved. But this solution is specially challenging as the engineers have to adapt the foundation, with an interface, between the concrete towers and the rock anchors. Not to forget the special design work of these anchors that needs to be done. Finally, the client was impressed and satisfied about the result. But more important: the project costs were below the initial budget.

High plinth for extra height

In another case, CTE Wind was approached by a global construction company and explained the challenge for its project in Chile, with over 35 WTGs. The customer needed an hub height of 4 meters more to increase the energy production and ensure the yield and so its income. They weren’t totally satisfied with a complex solution by one of CTE Wind’s competitors. That is why the construction company asked CTE Wind to find a simple, reliable, feasible and cost-effective solution. That is how the high plinth foundation was chosen: a solution already tested and implemented in multiple projects in Europe. The idea of this foundation is to reach higher hub height with a high pedestal. The tower stands 3 to 6 meters above the «ground level», keeping the gravity foundation independent from the tower system. Ideally the solution provides a longer anchor cage. CTE Wind’s engineering team designed the anchor cage for this project and determined the bolt length and steel quality. If needed CTE Wind can also prepare the detailed anchor cage drawing. After comparing the results of CTE Wind’s predesigns to the competitor’s solutions, the customer decided to go ahead with CTE Wind’s high plinth foundation. No difficulties in regards the construction have been reported. On the contrary, the Spanish expert of WTG foundation design was congratulated.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

Rock anchor and high plinth foundations

.

.

Two simply but effective foundation solutions are the rock anchor, designed for a wind park in Mexico and the high plinth solution for a wind farm in Chile. They are highly cost efficient, feasible and have proven to be very reliable in many projects.

Bilbao (ESP) – Special requests often demand tailormade solutions. But tailormade needs an high specialization and a lot of knowhow from the engineers in the specific field. In foundation design for wind turbine generator (WTG), this specific knowledge is not that common, except for CTE Wind International. Their senior engineers are often asked to find new design solutions. For this purpose, they resort to tried and tested instead of reinventing the wheel. Two simply but effective solutions are the rock anchor and the high plinth solution. They aren’t NEW solutions but are highly cost efficient, feasible and their reliability has been proved in many projects. This article features two project cases, among many others, where CTE Wind International designed a rock anchor for a wind park in Mexico and a high plinth foundation for a wind farm in Chile.

Cost savings thanks to rock anchor

In Mexico CTE Wind Ibérica was selected as WTG foundation designer by a Spanish EPC company. The project has more than 20 WTGs with concrete towers. The project analysis conducted by the Spanish expert in foundation design has led to the recommendation to deploy two different solutions in order to optimize the costs of project. In fact, the soil conditions showed that over a third of the wind turbines were planned on rocky ground. Rather than equipping all wind turbine with standard slab foundations, CTE Wind’s engineering team decided together with the customer to implement rock anchors. This solution uses the rock masses as a WTG foundation. In that way the construction company is able take advantage of the earth crust instead of building a slab foundation. The costs for the reinforced concrete and the construction work can be saved. But this solution is specially challenging as the engineers have to adapt the foundation, with an interface, between the concrete towers and the rock anchors. Not to forget the special design work of these anchors that needs to be done. Finally, the client was impressed and satisfied about the result. But more important: the project costs were below the initial budget.

High plinth for extra height

In another case, CTE Wind was approached by a global construction company and explained the challenge for its project in Chile, with over 35 WTGs. The customer needed an hub height of 4 meters more to increase the energy production and ensure the yield and so its income. They weren’t totally satisfied with a complex solution by one of CTE Wind’s competitors. That is why the construction company asked CTE Wind to find a simple, reliable, feasible and cost-effective solution. That is how the high plinth foundation was chosen: a solution already tested and implemented in multiple projects in Europe. The idea of this foundation is to reach higher hub height with a high pedestal. The tower stands 3 to 6 meters above the «ground level», keeping the gravity foundation independent from the tower system. Ideally the solution provides a longer anchor cage. CTE Wind’s engineering team designed the anchor cage for this project and determined the bolt length and steel quality. If needed CTE Wind can also prepare the detailed anchor cage drawing. After comparing the results of CTE Wind’s predesigns to the competitor’s solutions, the customer decided to go ahead with CTE Wind’s high plinth foundation. No difficulties in regards the construction have been reported. On the contrary, the Spanish expert of WTG foundation design was congratulated.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

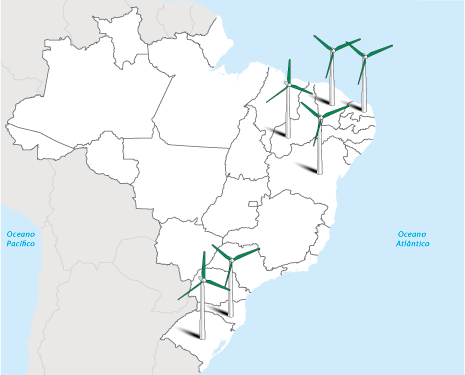

Pre-design studies for brazilian auction

The CTE WIND Brazil is pleased to announce one more of its diverse activities in the Brazilian market of wind turbines foundations. In the auction held in August 2018, the pre-design studies conducted by CTE WIND Brasil contributed to the commercialization of two wind farm projects, located in the state of Bahia and Rio Grande do Norte, with capacity to generate 85 MW and 70 MW respectively. The studies of pre-design were of paramount importance to make the projects economically and technically viable.

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies. However you may visit Cookie Settings to provide a controlled consent.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| PHPSESSID | session | This cookie is native to PHP applications. The cookie is used to store and identify a users' unique session ID for the purpose of managing user session on the website. The cookie is a session cookies and is deleted when all the browser windows are closed. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by Google. In addition to certain standard Google cookies, reCAPTCHA sets a necessary cookie (_GRECAPTCHA) when executed for the purpose of providing its risk analysis. |

| Cookie | Duration | Description |

|---|---|---|

| pll_language | 1 year | This cookie is set by Polylang plugin for WordPress powered websites. The cookie stores the language code of the last browsed page. |

| Cookie | Duration | Description |

|---|---|---|

| _gat | 1 minute | This cookies is installed by Google Universal Analytics to throttle the request rate to limit the colllection of data on high traffic sites. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assign a randomly generated number to identify unique visitors. |

| _gat_gtag_UA_151427895_1 | 1 minute | This cookie is set by Google Tag Manager and is used to throttle request rate and to store and track conversions. |

| _gid | 1 day | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the website is doing. The data collected including the number visitors, the source where they have come from, and the pages visted in an anonymous form. |