The SOFT-SPOT® Solution

H4a Windenergie B.V. / Coöperatie Zuidenwind

CTE Wind’s clients are also adopting this solution in many other wind farms worldwide. Argentina, Brazil, Chile, France, Lithuania, Indonesia, Mexico, Netherland, Russia, Serbia, Sweden and Thailand to name a few.

750 wind turbines around the globe are using CTE Wind’s Soft-spot® solution. The yellow circle outlines the soft layer.

SOFT-SPOT® in Kannus Windpark in Finland

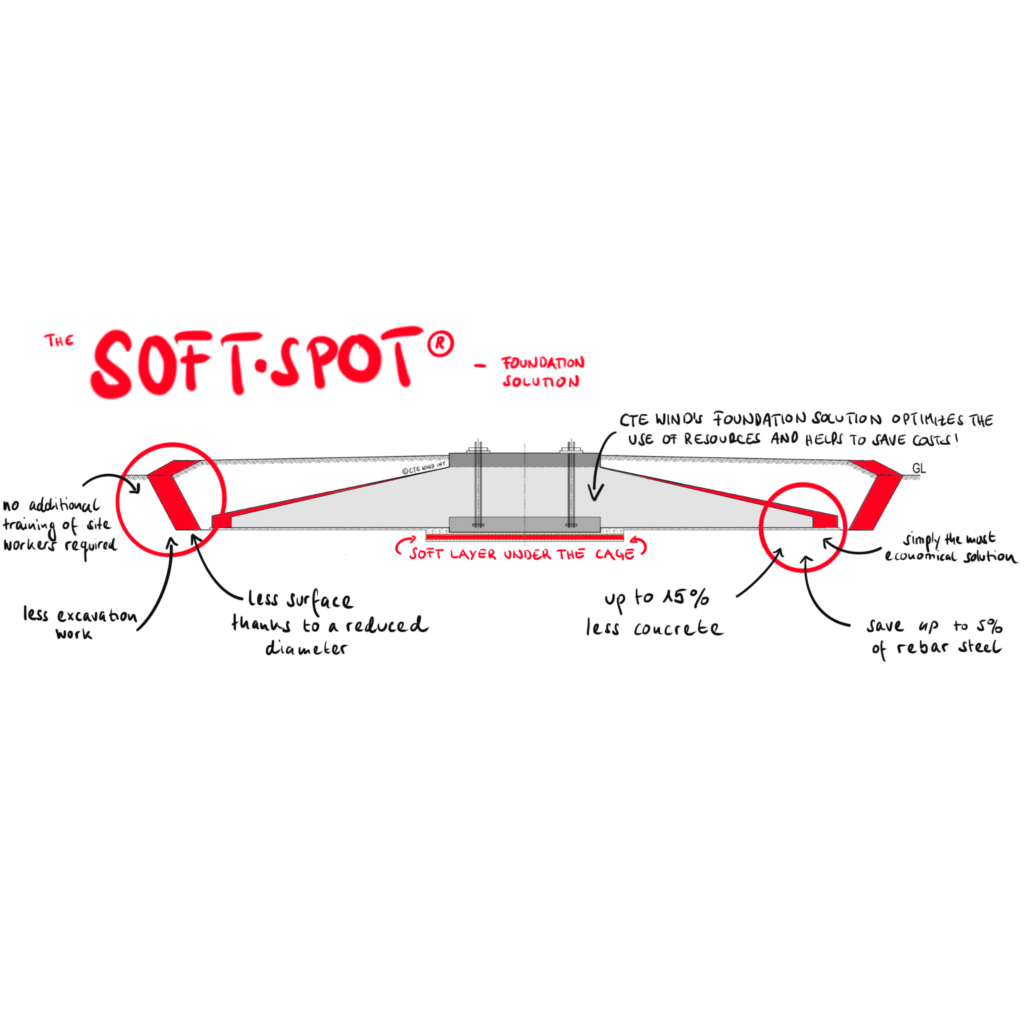

The SOFT-SPOT® was developed by CTE Wind’s engineering team and is implemented in various countries around the world. This foundation design optimizes the use of resources and helps to save concrete, reinforcement bars and less surface for the foundation. This reduces the time and costs.

La Richardais (FRA) – CTE Wind has already developed and implemented some projects since the launch of the SOFT-SPOT®. Several hundreds of the new foundation design are built around the world : Brazil, France, Lithuania, Indonesia, Mexico, Netherland, Russia, Serbia, Sweden and Thailand to name a few. As a result of his astonishing design the projects allow savings in concrete volume up to 15%, reduction of foundation diameter and total weight of reinforcement bars of 2-5%. In some cases what is even more important than the material costs is the available space : with SOFT-SPOT® you need less surface for the foundation. This reduces the time and excavation costs.

Layer of soft material

CTE WIND Civil Engineering presents to the market a new foundation system for wind turbines, a WTG shallow gravity foundation with SOFT-SPOT®. Through placing a layer of soft material below the central part of the foundation, the slab will effectively act as a ring foundation with respect to the soil-structure interaction. The bearing pressure of the WTG is concentrated at the annular contact surface closer to the edge of the slab. This increases the lever arm of the stabilizing moment. Therefore, the foundation diameter can be reduced in comparison to a standard foundation solution.

Simply the most economical foundation

Thanks to SOFT-SPOT® intelligent design less excavation work is needed. This reduces the machine costs. A major point is that no additional training of site workers is required for the construction of the soft layer. The construction is very easy and the material for the soft layer can be purchased cheaply all over the world. Or as one of CTE Wind’s client pointed out: It is simply the most economical foundation you can choose. (ctewind)

Please contact us if you are interested in knowing more about CTE Wind’s SOFT-SPOT®

What VRES 2018 can provide is not only the platform to understand the market intelligence, but also to get connected with potential local partners and leads of advanced stage renewable projects in Asia. Dates: 26-28 March in Nha Trang.

Geotechnical Services – Good ground for wind turbines

Interview with Ana Bielza, Senior Engineer CTE Wind Iberica

Head of Geotech Services CTE Wind International

Since 2019 CTE Wind provides geotechnical engineering services to their clients. Over the last six months, Ana Bielza, Senior Engineer at CTE Wind Iberica has taken part in over 45 projects. We have asked her what she actually does and why her role is crucial for the foundation design of wind turbine generators (WTG).

Can you briefly explain to us what a specialist in geotechnical engineering like you does?

Ana Bielza: Geotechnicians apply scientific methods and engineering principles to predict the response of the ground to the foundation requirements. They then deliver this information to the civil engineers so they can design foundations accordingly.

What is the difference between common geotechnical engineering for bridges or building compared to the WTG-geotechnics?

Ana Bielza: There are not many differences. The ground has to be investigated with similar methods (drillings, geophysics, lab tests, etc.) and the same kind of parameters are needed. But the ground capacity is usually not what determines the foundation size, because most of the time the soil strength transmitted by a turbine foundation is not high. Besides, settlements in general are not important in this type of structures. But rotational stiffness can rather be the main ground parameter to manage and sometimes it can even set the foundation size.

CTE Wind offers his services worldwide

You worked on over 45 projects in six months, which is quite a lot. In which countries did you take a look at the ground?

Ana Bielza: Yes, there were many. It looks like our services are very appreciated by the customers (She smiles delighted). I worked for projects in Argentina, Australia, Belgium, Brazil, Chile, India, Indonesia, Israel, Lithuania, Mexico, Netherlands, Peru, Russia, Spain, Tanzania, Tonga, Turkey, and Ukraine. Of course, every country has its peculiarities. And I not only mean the different ground types you can find but also how the different investigations that are conducted and how the results are delivered.

Looking back on these last months, what were the challenges? Can you maybe share one or two projects with us?

Ana Bielza: Challenging projects are usually the ones located on recent soils in seismic areas and near to the shore (high water table). For example, we have done several basic designs for a huge project in India with 1000 wind turbines, located on a saline desertic zone most of the year. But during the monsoon season the landscape becomes a swamp, with water at ground level. It is a region with an extreme seismic risks, on a recent granular soil (potentially liquefiable) and very aggressive to the concrete. We had to analyze the ground with just four boreholes in an area for 1000 turbines!

Sounds like fun. As far as we know, there are no known cases of significant damage from liquefaction in wind farms. So, how did you solve this problem?

Ana Bielza: Well, with only four drillings for such a huge area, it was mandatory to be conservative, therefore, and according to the client, we worked with two possible scenarios. We hope they were representative for the situation in most of the future turbine positions. The civil engineer then follows our specifications and designs the foundations accordingly with piles.

Trust is an important key factor

Could you tell us about another project?

Ana Bielza: Another challenging project has been the one in a country in South America, a wind farm with over 40 turbines. This was a constructive design where we had also drafted the geotechnical study from a factual report given by the customer, with 45 boreholes, 80 trial pits and 46 geophysical tests as well as an important amount of laboratory tests. The ground was good, a consolidated gravely soil -a conglomerate-, but seemed to be prone to suffer some dissolution because it had salt in its matrix.

What does it mean exactly?

Ana Bielza: The matrix describes the different layers a soil can have. The salt in the matrix can be dissolved by heavy rain or ground water. But even if the ground suffers an hypothetical dissolution, the remaining gravely soil would show enough strength and rigidity to carry the WTG. Besides, there was no water at all in the area, it was in a desert area.

Good conditions. What was the problem then?

Ana Bielza: Yes, but the client was pressuring us to set down categorically that there was no risk of dissolution, and there was no possibility at all for buoyancy. The geotechnics of the project showed good conditions for our SOFT-SPOT® foundation, but the wind farm owner seemed to have unfounded fears and wanted us to affirm that there was zero risk in this area. But zero risk does not exist. It was tricky to explain why there are no risk but we had to write about an hypothetical dissolution. Luckily, we finally came to an understanding. (ctewind)

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections.

For more Information about OUR-SERVICES please CONTACT US.

Cost saving wind turbine foundation design – CTE Wind toasts 750 Soft-spot® foundations

In the last 2 years over 50 project developers trusted CTE Wind’s Soft-spot® solution. Recently in Spain the expert of wind turbine foundations has won their third project, where the Soft-spot® solution was implemented.

Bilbao (Esp) / La Richardais (FRA) – CTE Wind Ibérica has won again a contract in Spain to calculate and design foundations with its Soft-spot® solution. This is an important milestone for CTE Wind International as now three wind farms on the Iberian Peninsula will take advantage of its cost saving design. In addition to these projects, CTE Wind’s clients are also adopting this solution in many other wind farms worldwide. Argentina, Brazil, Chile, France, Lithuania, Indonesia, Mexico, the Netherlands, Russia, Serbia, Sweden and Thailand to name a few. Over 50 wind farms around the globe, 750 wind turbines are using this resource saving solution which was introduced a while ago by CTE Wind.

« CTE Wind is proud of the confidence shown by its clients, and especially of the interest on applying the Soft-spot® solution», Chief executive Alexander MARTIN said and added « Our design provides interesting advantages and cost saving in material consumption and civil works while being easy to be built. »

Simply the most economical foundation

The Soft-spot® was developed by CTE Wind’s engineering team and is implemented in various countries around the world. As a result of his astonishing design this solution allows savings in concrete volume up to 15%, reduction of foundation diameter and total weight reduction of reinforcement bars of 7 to 9%. The earthwork to be handled is reduced too. In some cases, what is also important is the available space : with Soft-spot® you need less surface for the foundation. The construction is very easy and the material for the soft layer can be easily purchased for a low price all over the world.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

We are happy to announce our participation at this event which will take place in Bilbao 2 – 4 April. There are over 8,000 companies and 400+ exhibitors that have confirmed their presence. Please come and visit us at our stand n° 3-B42