Choose an office

Choose an office

Choose an office

Choose an office

Home > Our News

.

New Australian sales representative ensures greater customer service. Michael Wolff will be the first point of contact for all Australian customers.

Perth, WA / La Richardais, France —

CTE Wind International is with the appointment of Michael WOLFF, Professional Engineer MIEAust, in Perth WA, Australia represented on five continents.

Thanks to Mr. Wolff’s recruitment, the expert in foundation design for wind turbines is pushing ahead with its growth strategy in Australia. Backed-up by the headquarters in France, all customers in Australia and Asian-Pacific region will receive faster service and support from CTE Wind’s team.

About CTE Wind International

CTE Wind Civil Engineering is an international engineering consulting firm specialized in the design of onshore wind turbine foundations. CTE Wind has been active in the wind energy sector since 2003.

As of 2021, CTE Wind has designed, value-engineered or peer-reviewed foundations for over 22,500 turbines in 73 countries. CTE Wind has offices in Brazil, Poland, Portugal, Spain, USA and Asia. Most recently, the internationally successful company opened its North American office in 2020 in Denver CO, USA.

The company is a subsidiary of the CTE Group, a consulting firm, specialized in building and civil engineering. The CTE Group was founded in 1965 and today is one of the leaders in the structural engineering sector in France.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

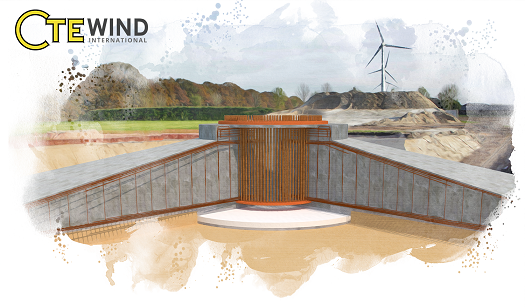

After our DNV certification in Germany, a high level technical review of the SOFT-SPOT™ solution has been done by DNV in the United States. Our experience shows that the Soft-Spot solution saves between 5 and 25 percent of foundation concrete, in addition to excavation volume reductions.

| CTE Wind’s SOFT-SPOT™ solution has already proven its merits in over 80 wind projects globally and over 1200 foundations built featuring this optimization solution. In the United States, we are proud to report that a high level technical review by DNV found the design to be “generally consistent with the US wind energy standards.” Furthermore, the review anticipates that “the Soft-Spot™ concept can also be applied to octagonal-shaped shallow depth concrete gravity foundations.” |

Our experience shows that the SOFT-SPOT™ solution saves between 5 and 25 percent of foundation concrete, in addition to excavation volume reductions. These savings represent a significant reduction of the Levelized Cost of Energy as well as reductions of the carbon footprint of wind energy.

If you want to learn more about CTE Winds SOLUTIONS please visite OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

WTG Foundation Design in France

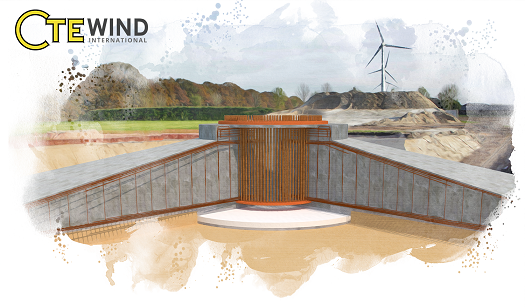

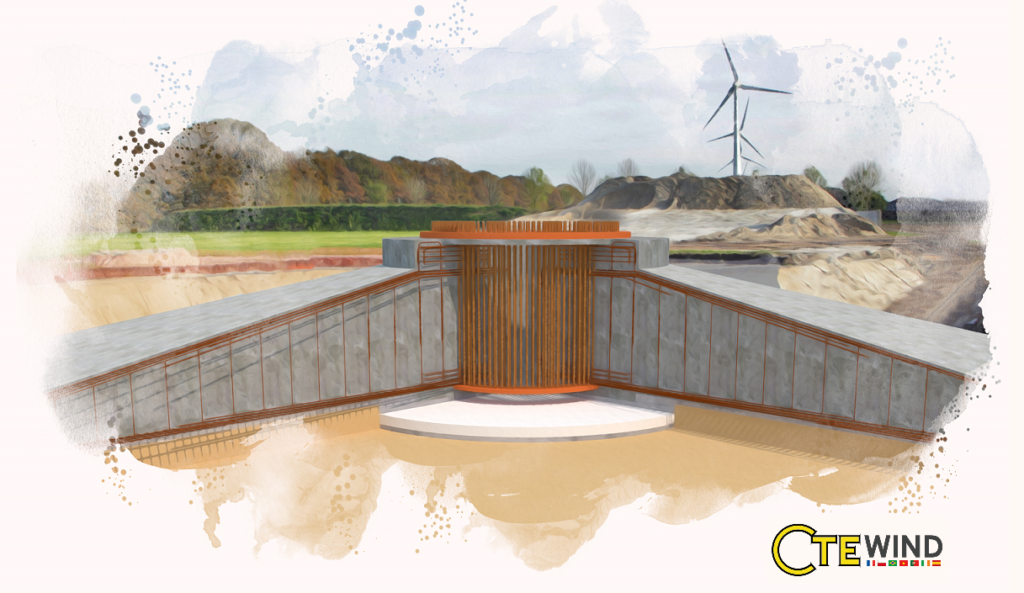

With the Soft-Spot® CTE Wind Civil Engineering captures the spirit of the times. The success is not only due to the new design solution. It is more a result of the developers increasing projects requirements and the size of the turbines. CTE Wind masters both easily.

La Richardais (FRA) – CTE Wind International, expert in foundation design for wind turbine generators, has his finger on the pulse of time with the Soft-spot® solution. Trademarked and patented in France (patent pending worldwide), 750 wind turbines use the resource saving solution worldwide. Over the half of the 50 realized projects related to the Soft-Spot® are located in France.

Cost savings

The success of the civil engineering company CTE Wind is not only due to the Soft-Spot®. It mainly relies on the fact that CTE Wind can master the increasing requirements of the wind energy developers. Wind farms have to be designed in a way that saves resources and allows fast set-up times; two important factors which determine the construction costs of WTG foundations.

A further driver and important point why developers choose CTE Wind is the increasing size of the turbines. Four to five years ago, the hub height of wind turbines ranged between 80 and 90 meters. Today the average hub heights of CTE Winds projects are between 110 and 120 meters. Some of the final designs even had a hub height far above average. The highest hub height ever calculated by CTE Wind stands in Salzgitter Germany with 166 meters.

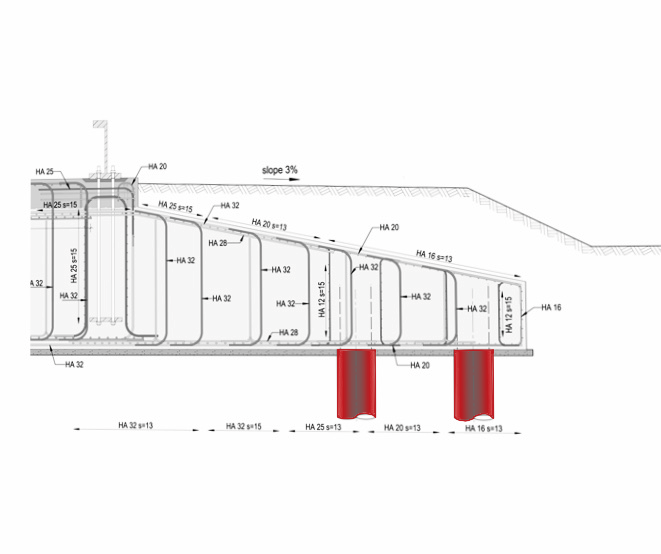

Adapting the design to soil conditions

CTE Wind adapts its foundations designs to the local soil conditions and in accordance with applicable national and international standards. To avoid extremely large foundations CTE Wind’s engineering team has found with the Soft-Spot® a good and reliable solution to meet the mentioned resource-saving requirements. The construction is very easy and it allows savings in concrete volume up to 15% and a total weight reduction of reinforcement bars of 7 to 9%. Thanks to the reduction of the foundation diameter the earthwork to be handled is also reduced. This leads to less surface use for the foundation.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

CTE Wind is celebrating its 20 years on the wind industry, specialized in WTG foundation design. During this time, foundations for over 30.000 WTGs worldwide have been designed by us.

An important number of them are rock anchored foundations. Several types can be applied, even some of them do not need the classical anchor cage.

These solutions provide, when the soil conditions are favourable, very small foundations that can often reduce the construction costs very effectively.

Projects performed by the team of CTE Wind International are found in Norway, Sweden, Finland, UK, Australia, Mexico, Spain, Uruguay, Namibia and more countries.

Get in touch for all topics around foundation design.

.

CTE Wind Expands Down Under: New Office Coming soon

Exciting news from the “Outback”! CTE Wind opens its doors in Australia, establishing a dedicated team ready to harness the wind energy potential. Joining forces with our Australian Sales Representative, Michael Wolff, is the experienced Ryan O’Flaherty.

Notably, Ryan brings essential local Professional Engineer (P.E.) licenses to the table, empowering our team to efficiently approve cost-effective foundation designs. Based on the picturesque Gold Coast, Queensland, on the other side of the Australian continent, Ryan’s strategic location positions us well for regional impact.

About CTE Wind International

CTE Wind Civil Engineering is an international engineering consulting firm specialized in the design of onshore wind turbine foundations. CTE Wind has been active in the wind energy sector since 2003.

As of 2023, CTE Wind has designed, value-engineered or peer-reviewed foundations for over 28,500 turbines in 75 countries. CTE Wind has offices in Brazil, Poland, Portugal, Spain, USA and Asia. Most recently, the internationally successful company opened its North American office in 2020 in Denver CO, USA.

The company is a subsidiary of the CTE Group, a consulting firm, specialized in building and civil engineering. The CTE Group was founded in 1965 and today is one of the leaders in the structural engineering sector in France.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

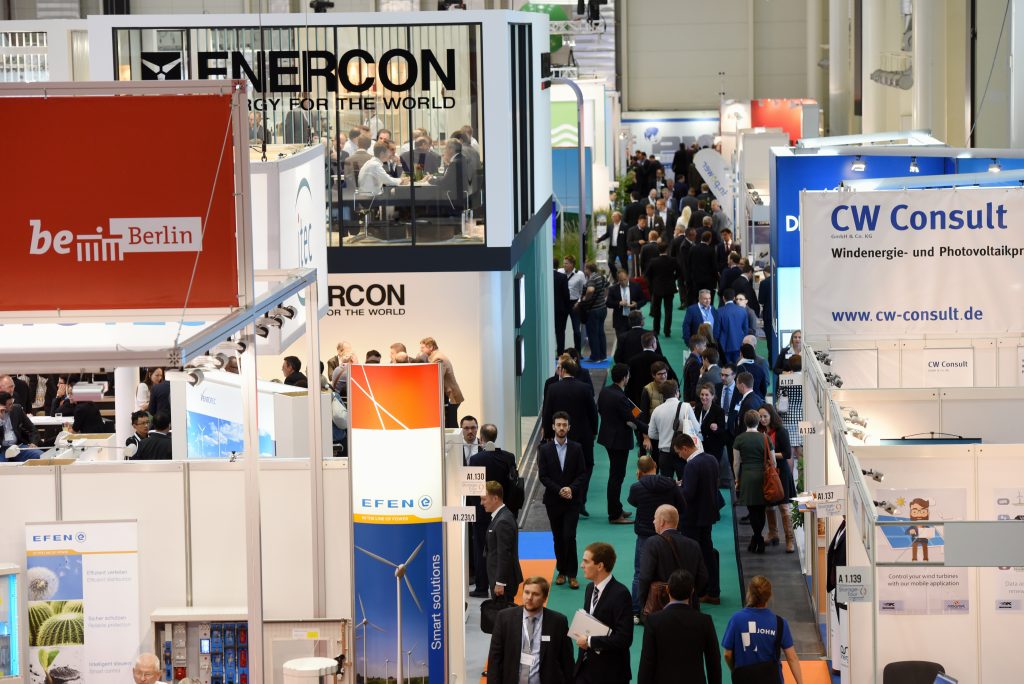

From 27 to 30 September 2022, Hamburg will become an energy hub for the world. For four days, at WindEnergy Hamburg everything at the trade show site will revolve around generating energy from wind and its exploitation.

CTE Wind partecipates in Hamburg with an own stand.

Leading business and union representatives provided diverse insights into all areas of the industry, with plenty of facts and figures. So as to cover the huge impending need for renewable energies, they highlighted the significance of personal exchange and knowledge transfer on an equal footing between industry, research institutions and policy

Alexander MARTIN CEO of CTE Wind International, along with the country Managers, engineering team and sales representatives of de CTE Wind offices worldwide will attend at the largest renewables conference dedicated to the wind energy market in Europe and all over the world. This is an excellent opportunity for interested companies to meet our sales team, learn more about CTE Wind’s expertise in civil engineering and foundations and discuss future collaborations..

Do not hesitate to contact us to organize a meeting.

See you soon in Hamburg.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

Hamburg, Germany

September 27th to 30th, 2022

Foundation piles transfer dynamic turbine loads to lower-lying ground, thereby providing overall support to the foundation and the turbine tower. Geotechnical and soil-structure interaction expertise is a must for designing wind turbine foundation piles. CTE Wind designed piles with lengths varying from 10 to 70 meters.

Foundation piles transfer loads from the wind turbine foundation to lower-lying ground, thereby providing overall support to the structure. These piles carry concentrated loads and are subject to fatigue. As such, careful assessment of geotechnical conditions and proper interpretation of the soil reports’ drilling logs and laboratory data are critical, which is why CTE Wind has senior geotechnical engineers working on wind farm projects worldwide.

CTE Wind’s pile foundation designs include driven, bored and drilled piles, as well as vibro and Franki piles. Once a pile solution has been selected as most appropriate for the site conditions, the number, lengths and diameters of the piles are determined based on the stiffness of piles and the loads to be carried. Piles are designed

In recent projects, CTE Wind has designed pile foundations with lengths varying from 10 to 70 meters. The latter, 70-meter pile foundations were designed and built in Asia in different nearshore projects on an intertidal sea-zone. CTE Wind also provided pile designs in Belgium, France, Germany, The Netherlands, Brazil, Serbia, Ukraine, Russia, and Finland to name a few.

If you want to learn more about CTE Wind International and CTE Winds PILE FOUNDATIONS please visite OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

.

CTE Wind inaugurates its first North American office in Broomfield, Colorado. Senior Engineer Jomâa Ben-Hassine (PhD) will oversee the structural engineering and geotechnical projects in the US and Canada.

Broomfield, CO / La Richardais, France — CTE Wind International, a consultancy specialized in the structural design of onshore foundations for wind turbine generators (WTGs), is pleased to announce the official opening of its North American office – CTE WIND USA, Inc. – in Broomfield, Colorado (Denver metro area).

« The decision to open our new office in the State of Colorado is a sensible choice for us and for our clients, » says CTE Wind International CEO Alexander MARTIN. « Denver is near the geographic center of the country and is at the heart of the wind belt. From Denver International Airport, our office colleagues can reach most project sites in a few hours and can visit with our North American clients easily, » he explains.

The Colorado office is dedicated to supporting the needs of our North American clients. Our customers on both sides of the Atlantic asked CTE Wind for a North American presence. They can now benefit from the same responsiveness and know-how they have come to expect from the CTE Wind offices in France (HQ), Brazil, Poland, Portugal, Spain and in Asia.

Senior Engineer Jomâa Ben-Hassine (PhD, PE, P.Eng., ing.) who is leading the structural and geotechnical consultancy will serve as Director of Operations & Engineering in the US and Canada. Dr. Ben-Hassine is a civil engineer licensed in twenty US states and three Canadian provinces. He has accumulated over 30 years of practical experience in geotechnical engineering, structural engineering, foundation design, soil-structure interaction, reliability-based design, geohazard recognition and mitigation and risk assessment. He is active on several technical and standard development committees and has taken on leadership roles in multiple professional organizations (AWEA’s WTSC, ARESCA, IEC, and ASCE).

« We are very happy to have Jomâa Ben-Hassine on board of CTE Wind USA., » says MARTIN. « He brings in longstanding experience in wind and solar energy and knows the US and European standards and guidelines. North American EPC/BOP contractors and developers will benefit from the best of the two worlds, especially when it comes to bigger wind turbines above 4 MW with higher hub heights. »

CTE Wind Civil Engineering is an international engineering consulting firm specialized in the analysis and design of onshore wind turbine foundations. CTE Wind has been active in the wind energy sector since 2003. As of 2019, CTE Wind has designed, value-engineered or peer-reviewed foundations for over 17,500 turbines in 67 countries. CTE Wind is headquartered in France and has offices in Brazil, Poland, Portugal, Spain, USA and Asia.

The company is a subsidiary of the CTE Group, a consulting firm, specialized in building and civil engineering. The CTE Group was founded in 1965 and today is one of the leaders in the structural engineering sector.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

Rock anchor and high plinth foundations

.

.

Two simply but effective foundation solutions are the rock anchor, designed for a wind park in Mexico and the high plinth solution for a wind farm in Chile. They are highly cost efficient, feasible and have proven to be very reliable in many projects.

Bilbao (ESP) – Special requests often demand tailormade solutions. But tailormade needs an high specialization and a lot of knowhow from the engineers in the specific field. In foundation design for wind turbine generator (WTG), this specific knowledge is not that common, except for CTE Wind International. Their senior engineers are often asked to find new design solutions. For this purpose, they resort to tried and tested instead of reinventing the wheel. Two simply but effective solutions are the rock anchor and the high plinth solution. They aren’t NEW solutions but are highly cost efficient, feasible and their reliability has been proved in many projects. This article features two project cases, among many others, where CTE Wind International designed rock-anchored foundations for a wind park in Mexico and a high plinth foundation for a wind farm in Chile.

Cost savings thanks to rock anchors

In Mexico, CTE Wind Ibérica was selected as WTG foundation designer by the EPC company. The project consisted of more than 20 concrete tower WTGs. The project analysis conducted by the foundation design expert has led to the recommendation to deploy two different solutions in order to optimize the costs of project. In fact, the soil conditions showed that over a third of the wind turbines were planned on rocky ground. Rather than equipping all wind turbine with standard slab foundations, CTE Wind’s engineering team decided together with the customer to implement rock anchors. This solution uses the rock mass as a WTG foundation. In that way the construction company is able take advantage of the earth crust instead of building a slab foundation. The costs for the reinforced concrete and the construction work can be saved. But this solution is specially challenging as the engineers have to adapt the foundation, with an interface, between the concrete towers and the rock anchors. Not to forget the special design work of these anchors that needs to be done. Finally, the client was impressed and satisfied about the result. But more important: the project costs were below the initial budget.

High plinth for extra height

In another case, CTE Wind was approached by a global construction company and explained the challenge for its project in Chile, with over 35 WTGs. The customer needed an hub height of 4 meters more to increase the energy production and ensure the yield and so its income. They weren’t totally satisfied with a complex solution by one of CTE Wind’s competitors. That is why the construction company asked CTE Wind to find a simple, reliable, feasible and cost-effective solution. That is how the high plinth foundation was chosen: a solution already tested and implemented in multiple projects in Europe. The idea of this foundation is to reach higher hub height with a high pedestal. The tower stands 3 to 6 meters above the «ground level», keeping the gravity foundation independent from the tower system. Ideally, the solution provides a longer anchor cage. CTE Wind’s engineering team designed the anchor cage for this project and determined the bolt length and steel quality. If needed, CTE Wind can also prepare detailed anchor cage drawings. After comparing the results of CTE Wind’s predesigns to the competitor’s solutions, the customer decided to go ahead with CTE Wind’s high plinth foundation. No difficulties in regards the construction have been reported. On the contrary, the Spanish expert of WTG foundation design was congratulated.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies. However you may visit Cookie Settings to provide a controlled consent.