Elige una oficina

Elige una oficina

The anchor cage design solution allows to optimize the foundation design and so the bill of concrete and steel quantities.

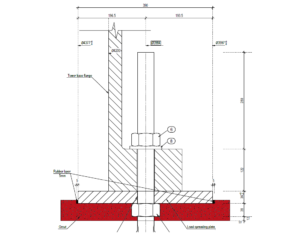

In the US a mandatory service from the structural engineer, in Europe delivered by the OEM: the anchor cage design. A well-designed anchor cage, or bolt cage, optimizes the bill of quantities of a wind turbine foundation (WTG) foundation. This special knowhow – or in French «savoir-faire» – of inhouse cage design leads CTE Wind to sophisticated foundation solutions such as the rock adaptor or the high plinth. The last mentioned helps to reach higher hub heights thanks his high pedestal. The tower stands 3 to 6 meters above the «ground level». The solution ideally provides also the design of the anchor cage. CTE Wind’s engineering team develops the cage and determines the bolt length, the pre-stress loads, the steel quality and all other necessary parameters.

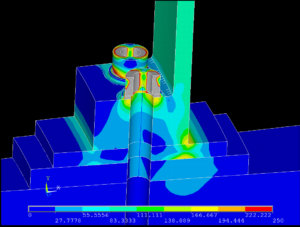

CTE Wind uses for the design of anchor cages the finite element method (FEM) which allows to analyze the behavior of structures with complex geometries and strong loads. The picture above shows the stress distribution in a tower base flange connection to the cage. Models like that help to verify structural integrity. FEM in combination with CTE Winds «savoir-faire», allows – in case something goes wrong during construction phase – to find repair solutions. Several clients have saved money and time thanks to CTE Wind’s pathology experience and FEM-skills.

Please contact us if you are interested in knowing more about CTE Wind’s anchor cage design.