Onshore Wind Energy Applications

Experts in Foundation Design

From 1 to 12 MW wind turbines

According to Bloomberg New Energy Finance in 2019 developers worldwide have globally

commissioned a little over 45GW of onshore wind turbines. CTE Wind designed, valueengineered

or peer-reviewed foundations close to 1,500 WTG-foundations around the globe,

which represents around 5 GW of the installed onshore wind energy in 2019. A good result

for the 30 engineers working together worldwide. CTE Wind is an international engineering

consulting firm, headquartered in France, and specialized in the analysis and design of

onshore wind turbine foundations. Its engineering services lead to inventive foundation

solutions for wind turbines. In Rotterdam, they have designed the foundation for GE’s giant

12 MW Haliade X. But they are also with familiar with smaller 1 MW machines carried by

wooden towers. «Thanks to our experienced civil, structural and geotechnical senior

engineers the design of those wind turbine foundations worldwide are only a little challenge

to us», said Alexander MARTIN, CEO of CTE Wind International, «regardless if it is for new

turbine models from the top manufacturers or less common WTG-models from smaller or

local manufacturers», he added.

Biggest wind park in France, Poland and Spain

The sum of all experiences made since 2003 is the reason why CTE Wind’s engineering

team with offices in Brazil, Poland, Portugal, Spain, USA and Asia are often the first

choice for OEMS, wind park developers and EPC/BoP contractors. «That is how we

achieved to do over 17,500 wind turbines in 67 countries and without any failures», continues

MARTIN. One of CTE Winds main goals is to deliver foundation designs that optimizes the

use of resources and help to save concrete and reinforcement steel. Such a solution is the

patented SOFT-SPOT®, a gravity foundation with a soft layer under the anchor cage. Each

project receives an adapted design solution to the specific soil conditions. In Finland CTE

Wind designed a rock anchor solution when its engineers also designed a near-shore

foundation in Asias Mekong-Delta. «The trust of our customers leads us not only to

design special and new solutions but also the foundations for the biggest wind parks in

France, Spain and Poland. We are thrilled when we can play an important role in a wind farm

project. This shows the confidence of our customers in our designs and is also an

encouragement for us to continue to perform well», he ends.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

From 1 to 12 MW wind turbines

Research & Development

CTE Wind R&D and Consulting services are the first choice when it comes to foundation design regardless of the WTG-manufacturer, model, size, power or soil conditions. Thanks to internal R&D-Team with senior engineers, holding over 100 years of cumulated experience in the design of wind turbine foundations, nothing is impossible.

La Richardais (FRA) – In 2019 Developers worldwide have globally commissioned a little over 45GW of onshore wind turbines. According to Bloomberg New Energy Finance, the Danish firm Vestas remained this way the world’s leading wind turbine supplier, with Spanish-German wind engineering company Siemens Gamesa a strong second. Chinas manufacturer number one Goldwind was third in the rankings, while US-Leader GE Renewable Energy’s secured its fourth place. Together the top four manufacturers accounted for 55 percent of the market share.

100 years of cumulated experience

This statement applies more or less also to CTE Wind, which calculated, designed and evaluated about 5000 WTG-foundations in 2019 around the globe. Thanks to CTE Wind’s internal R&D, with senior engineers holding over 100 years of cumulated experience in the design of wind turbine foundations worldwide, new turbine models from the top manufacturers as well as less common WTG-models from smaller or local manufacturers are only a little challenge. CTE Wind engineering services lead to state-of-the-art foundation solutions for wind turbines. Regardless of whether it is a prototype, such as GE’s giant 12 MW Haliade X or smaller 1 MW machine, from German ENO or Dutch EWT.

Wooden tower

Also worth mentioning: the different types of towers for wind turbines. Concrete (hollow foundation) and steel towers are well known to CTE Wind. Both tower systems are suitable to be used alone or in combination. Even foundations with wooden towers were calculated and designed by CTE Wind in the past. The sum of all experiences made during the projects since 2003 is the reason why their engineering services in foundation design are the first choice for wind turbine manufacturers, wind park developers and EPC contractors worldwide.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

Soft-Spot® Solution – Foundation Design Helps To Save Resources

«To work with CTE Wind as designer was nice. The speed of response and reliability of the planning has been a winning experience for us.»

Arjan Louwerse from H4a Windenergie B.V.

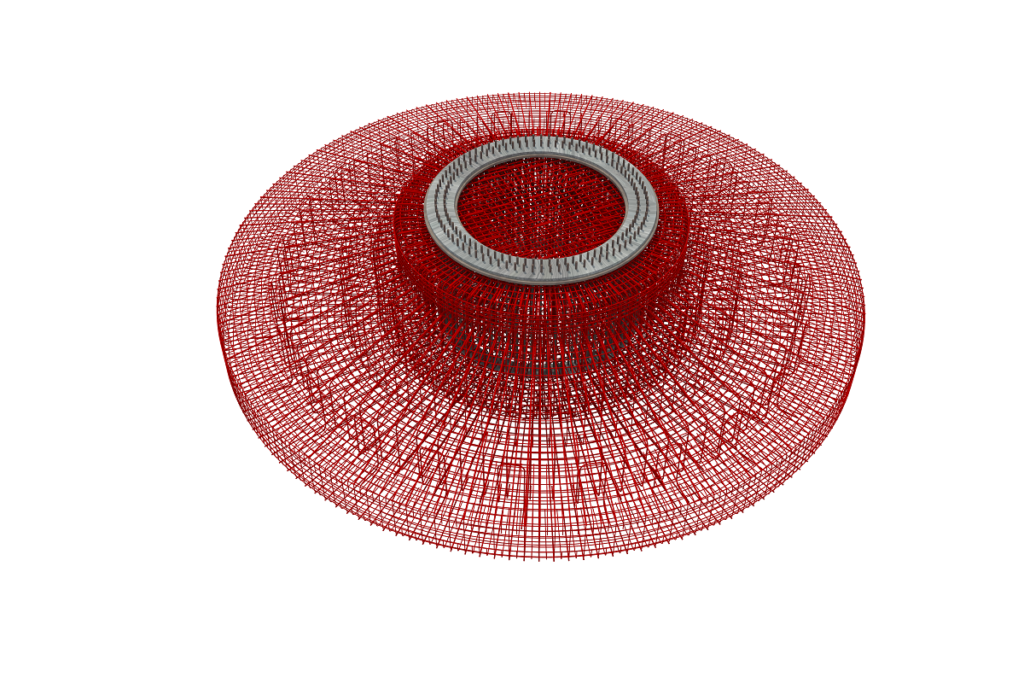

Coöperatie Zuidenwind has poured the concrete for the foundation in Heibloem in the Netherlands and created the basis for the installation of their wind turbines. The foundation design and calculation for this project was done by CTE Wind Civil Engineering. The expert in foundation design WTG suggested their Soft-Spot® instead of a typical pile foundation.

Heibloem (NL) / La Richardais (FR) – The Netherlands soil consistsof unconsolidated, very young sediments. Due to the proximity of the low-lying part of the European continent, the basin of the North Sea, the bottom rarely rises higher than 30 m above sea level. In the areas along the coast (provinces of Groningen, Friesland, Noord-Holland, Zuid-Holland, Zeeland) the surface soil layers consist mainly of clay deposits. In the west of the Netherlands the clays are replaced by lowland moors (peat). To sum up: in the Netherlands, pile foundations are mandatory for wind turbines because of the concentrated forces occurring on little surface area. Except in Heibloem, where the ground is exceptionally stable. So good, in fact, that CTE Wind offered its resource-saving Soft-Spot® instead of the usual foundation.

Soft-Spot® in the Netherlands

The Soft-Spot® was developed by CTE Wind’s engineering team and is implemented in various countries around the world. «It was simply the most economical foundation we could choose », Arjan Louwerse from H4a Windenergie B.V. says. He is the project manager for Coöperatie Zuidenwind wind turbines. This foundation design optimizes the use of resources and helps to save up to 15 % of concrete and 2 to 5 % of reinforcement steel. In some cases what is even more important than the costs is the available space : with Soft-Spot® you need less surface for the foundation. This reduces the time and excavation costs. «The philosophy to reduce the costs of the Soft-Spot® was also a good point of discussion with our client. From the beginning we had a good feeling with the design», he explains.

In fact thanks to the new design the outer diameter of the foundation was 1.1m smaller compared to a typical foundation design. This resulted in a reduction of 11 % of concrete and 3 % of steel – or more precisely about 100m3 of reinforced concrete. «To work with CTE Wind as designer was nice. The speed of response and reliability of the planning has been a winning experience for us», Louwerse added. In spring 2020 the wind turbine will arrive together with the largest blades ever installed onshore in the Netherlands. (ctewind)

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.