Choose an office

Choose an office

Choose an office

Choose an office

Home > Our News

CTE Wind commissioned the Spanish University of Burgos to carry out a series of tests with the Soft-Spot™®. The structural tests are intended to prove once again if and how the resource-saving wind turbine foundation solution for “onshore” wind turbines works.

Burgos (ESP)/La Richardais (FRA) – The University of Burgos was entrusted with testing the patented Soft-Spot™® foundation solution from CTE Wind Civil Engineering for its functioning and safety at the end of 2021. The results of the test campaign, which ended at the end of May, confirmed what had already been demonstrated from many certification bodies worldwide and in various finite element models (FEM): The Soft-Spot™® works and is safe.

The Soft-Spot™® changes the stress distribution on the ground compared to a standard slab foundation. Due to central EPS soft layer, higher soil stresses are applied under the remaining ring.

As a result, a wind turbine with a Soft-Spot™® foundation will gap much later than a foundation without a soft layer, with the same foundation diameter. This increases the stability.

…use the Soft-Spot™® worldwide. The first project with the patented CTE Wind solution has been in place in 2019 in Thailand in a wind farm with 60 turbines. Each turbine has a hub height of 157 meters. Originally, a shallow foundation with 1,192 cubic meters of concrete and a diameter of 27.4 meters was planned.

But the excavation was not allowed to exceed more than 25 meters diagonally. Thanks to the soft layer under the foundation, the diameter could be reduced to 24.5 meters; minus 210 cubic meters of concrete (-18 percent) and 11 tons of reinforcing steel (-9 percent). The certifying body of DNV in Hamburg ensured that everything proceeded correctly and according to international standards during the design phase.

About CTE Wind Civil Engineering and the Soft-Spot™®

The Soft-Spot™® was developed by the French company CTE Wind Civil Engineering SAS. CTE Wind is an international engineering company specializing in the design and calculation of onshore foundations for wind turbines. The solution optimizes the existing and well-functioning system of shallow foundations by integrating known knowledge from structural engineering. Thus, a soft layer (EPS) is simply placed under the center of the foundation so that the forces of the wind turbine are transferred into the ground in a ring shape instead of onto the entire surface.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

Rock anchor and high plinth foundations

.

.

Two simply but effective foundation solutions are the rock anchor, designed for a wind park in Mexico and the high plinth solution for a wind farm in Chile. They are highly cost efficient, feasible and have proven to be very reliable in many projects.

Bilbao (ESP) – Special requests often demand tailormade solutions. But tailormade needs an high specialization and a lot of knowhow from the engineers in the specific field. In foundation design for wind turbine generator (WTG), this specific knowledge is not that common, except for CTE Wind International. Their senior engineers are often asked to find new design solutions. For this purpose, they resort to tried and tested instead of reinventing the wheel. Two simply but effective solutions are the rock anchor and the high plinth solution. They aren’t NEW solutions but are highly cost efficient, feasible and their reliability has been proved in many projects. This article features two project cases, among many others, where CTE Wind International designed rock-anchored foundations for a wind park in Mexico and a high plinth foundation for a wind farm in Chile.

Cost savings thanks to rock anchors

In Mexico, CTE Wind Ibérica was selected as WTG foundation designer by the EPC company. The project consisted of more than 20 concrete tower WTGs. The project analysis conducted by the foundation design expert has led to the recommendation to deploy two different solutions in order to optimize the costs of project. In fact, the soil conditions showed that over a third of the wind turbines were planned on rocky ground. Rather than equipping all wind turbine with standard slab foundations, CTE Wind’s engineering team decided together with the customer to implement rock anchors. This solution uses the rock mass as a WTG foundation. In that way the construction company is able take advantage of the earth crust instead of building a slab foundation. The costs for the reinforced concrete and the construction work can be saved. But this solution is specially challenging as the engineers have to adapt the foundation, with an interface, between the concrete towers and the rock anchors. Not to forget the special design work of these anchors that needs to be done. Finally, the client was impressed and satisfied about the result. But more important: the project costs were below the initial budget.

High plinth for extra height

In another case, CTE Wind was approached by a global construction company and explained the challenge for its project in Chile, with over 35 WTGs. The customer needed an hub height of 4 meters more to increase the energy production and ensure the yield and so its income. They weren’t totally satisfied with a complex solution by one of CTE Wind’s competitors. That is why the construction company asked CTE Wind to find a simple, reliable, feasible and cost-effective solution. That is how the high plinth foundation was chosen: a solution already tested and implemented in multiple projects in Europe. The idea of this foundation is to reach higher hub height with a high pedestal. The tower stands 3 to 6 meters above the «ground level», keeping the gravity foundation independent from the tower system. Ideally, the solution provides a longer anchor cage. CTE Wind’s engineering team designed the anchor cage for this project and determined the bolt length and steel quality. If needed, CTE Wind can also prepare detailed anchor cage drawings. After comparing the results of CTE Wind’s predesigns to the competitor’s solutions, the customer decided to go ahead with CTE Wind’s high plinth foundation. No difficulties in regards the construction have been reported. On the contrary, the Spanish expert of WTG foundation design was congratulated.

If you want to learn more about CTE Wind International you can read more articles about projects and news in OUR-PROJECTS & OUR-NEWS – sections. For more Information about OUR-SERVICES please CONTACT US.

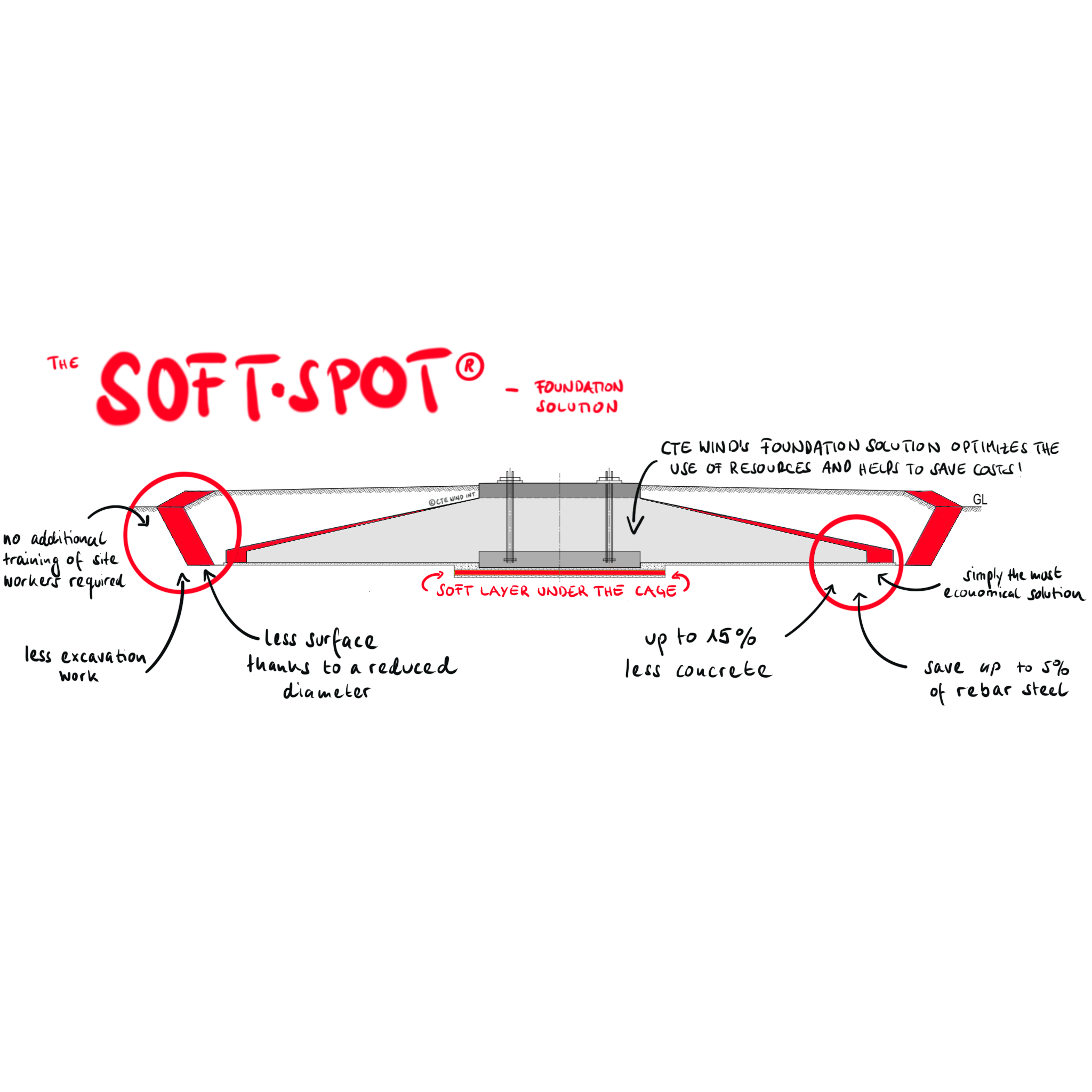

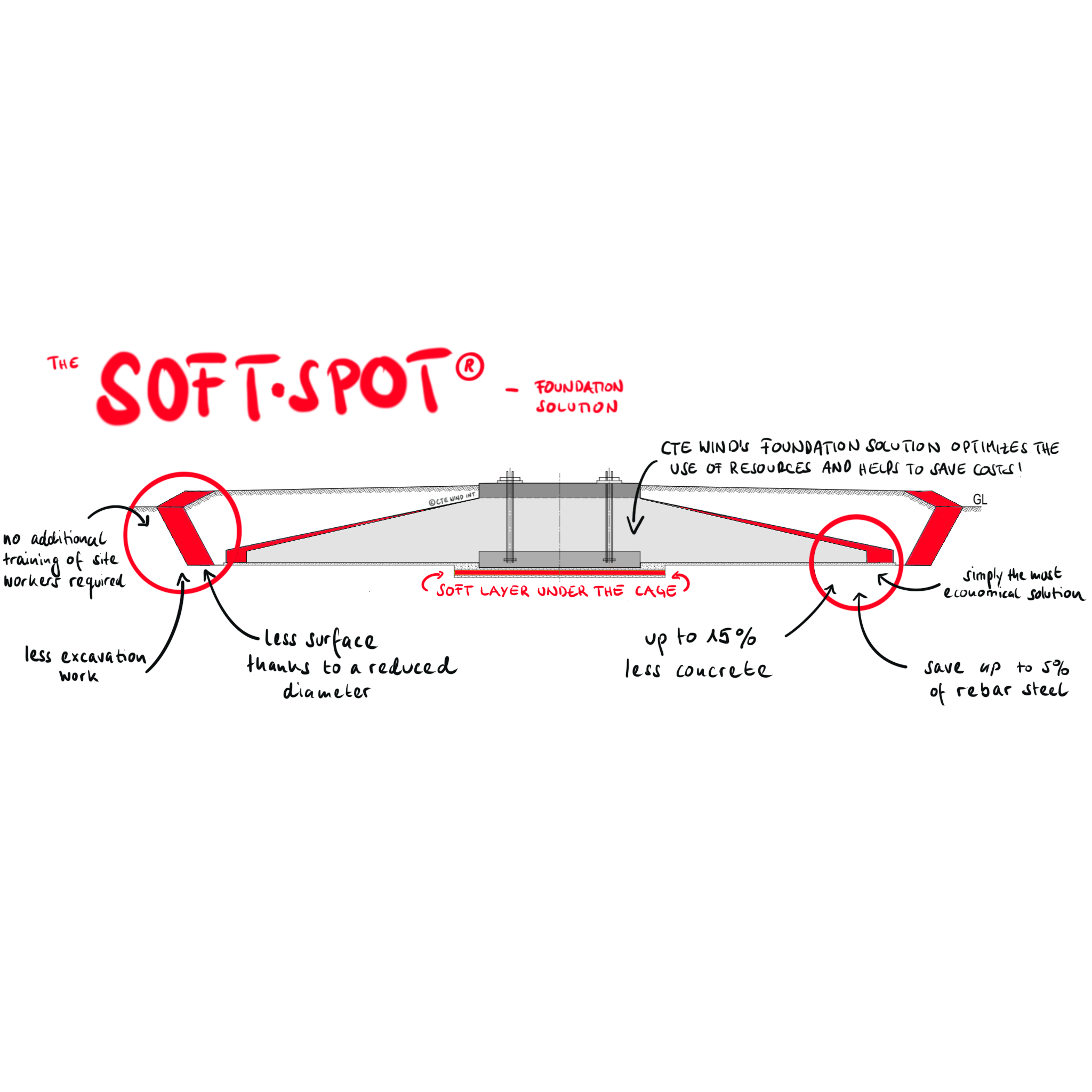

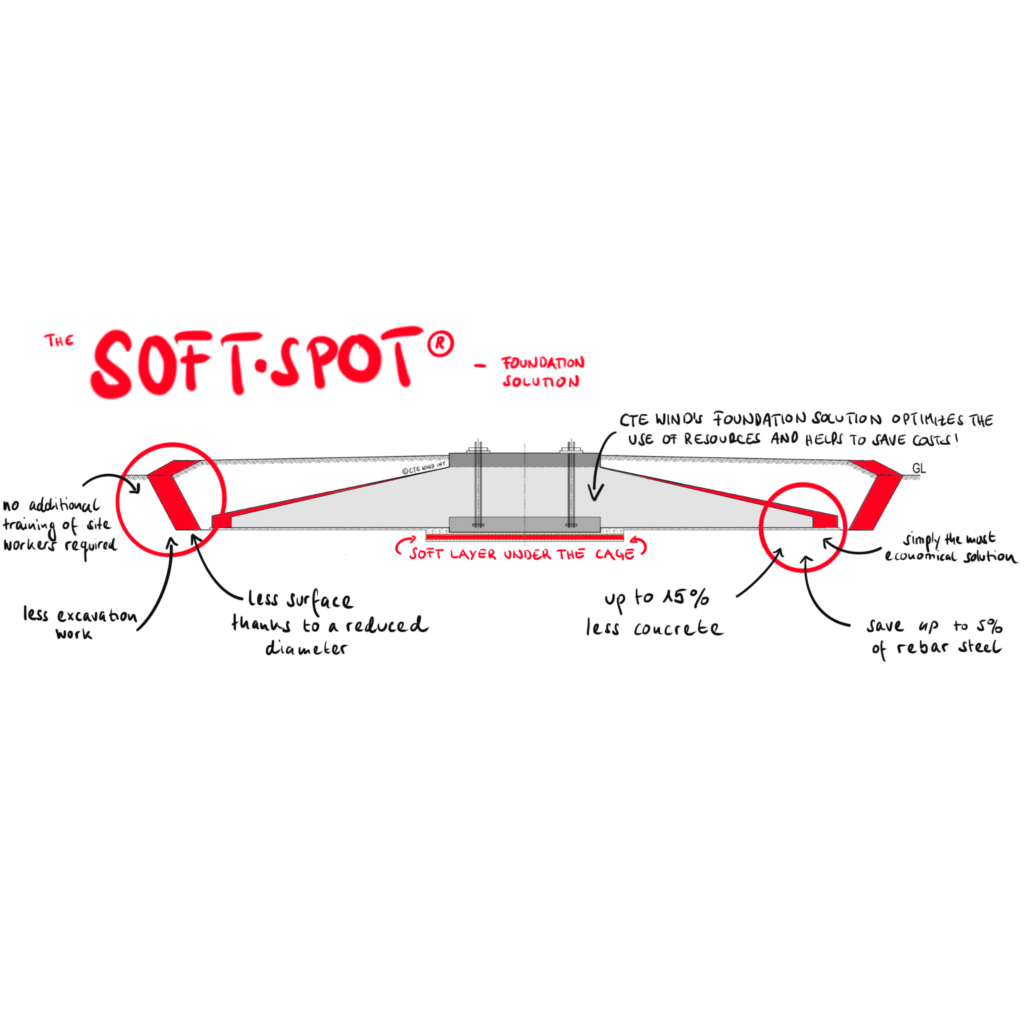

The SOFT-SPOT® was developed by CTE Wind’s engineering team and is implemented in various countries around the world. This foundation design optimizes the use of resources and helps to save concrete, reinforcement bars and less surface for the foundation. This reduces the time and costs.

La Richardais (FRA) – CTE Wind has already developed and implemented some projects since the launch of the SOFT-SPOT®. Several hundreds of the new foundation design are built around the world : Brazil, France, Lithuania, Indonesia, Mexico, Netherland, Russia, Serbia, Sweden and Thailand to name a few. As a result of his astonishing design the projects allow savings in concrete volume up to 15%, reduction of foundation diameter and total weight of reinforcement bars of 2-5%. In some cases what is even more important than the material costs is the available space : with SOFT-SPOT® you need less surface for the foundation. This reduces the time and excavation costs.

CTE WIND Civil Engineering presents to the market a new foundation system for wind turbines, a WTG shallow gravity foundation with SOFT-SPOT®. Through placing a layer of soft material below the central part of the foundation, the slab will effectively act as a ring foundation with respect to the soil-structure interaction. The bearing pressure of the WTG is concentrated at the annular contact surface closer to the edge of the slab. This increases the lever arm of the stabilizing moment. Therefore, the foundation diameter can be reduced in comparison to a standard foundation solution.

Thanks to SOFT-SPOT® intelligent design less excavation work is needed. This reduces the machine costs. A major point is that no additional training of site workers is required for the construction of the soft layer. The construction is very easy and the material for the soft layer can be purchased cheaply all over the world. Or as one of CTE Wind’s client pointed out: It is simply the most economical foundation you can choose. (ctewind)

Please contact us if you are interested in knowing more about CTE Wind’s SOFT-SPOT®

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies. However you may visit Cookie Settings to provide a controlled consent.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| PHPSESSID | session | This cookie is native to PHP applications. The cookie is used to store and identify a users' unique session ID for the purpose of managing user session on the website. The cookie is a session cookies and is deleted when all the browser windows are closed. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by Google. In addition to certain standard Google cookies, reCAPTCHA sets a necessary cookie (_GRECAPTCHA) when executed for the purpose of providing its risk analysis. |

| Cookie | Duration | Description |

|---|---|---|

| pll_language | 1 year | This cookie is set by Polylang plugin for WordPress powered websites. The cookie stores the language code of the last browsed page. |

| Cookie | Duration | Description |

|---|---|---|

| _gat | 1 minute | This cookies is installed by Google Universal Analytics to throttle the request rate to limit the colllection of data on high traffic sites. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assign a randomly generated number to identify unique visitors. |

| _gat_gtag_UA_151427895_1 | 1 minute | This cookie is set by Google Tag Manager and is used to throttle request rate and to store and track conversions. |

| _gid | 1 day | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the website is doing. The data collected including the number visitors, the source where they have come from, and the pages visted in an anonymous form. |