Choose an office

Choose an office

Choose an office

Choose an office

Home > Our Solutions

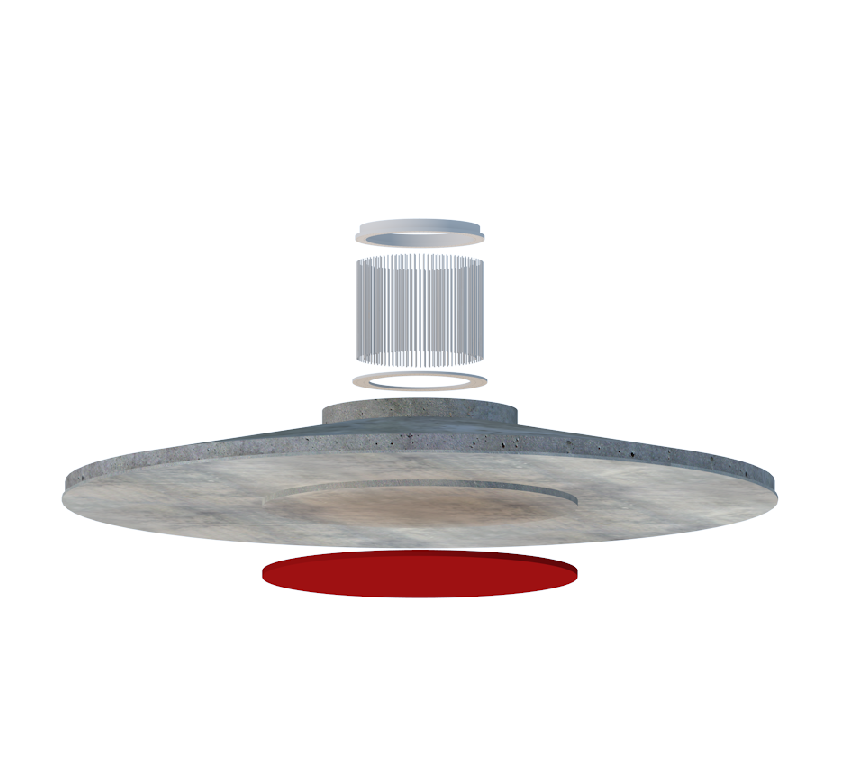

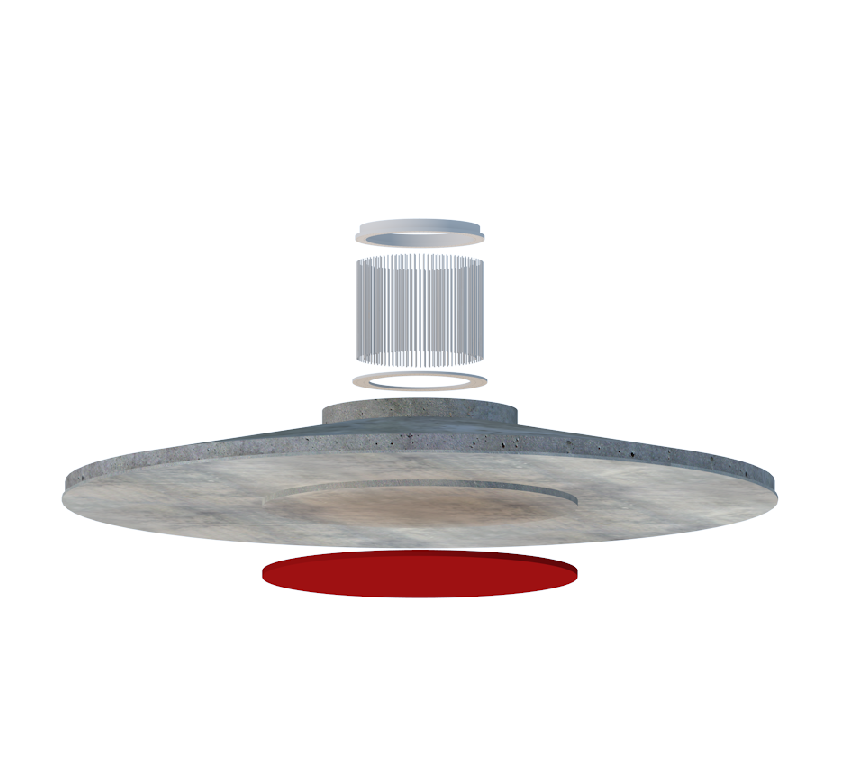

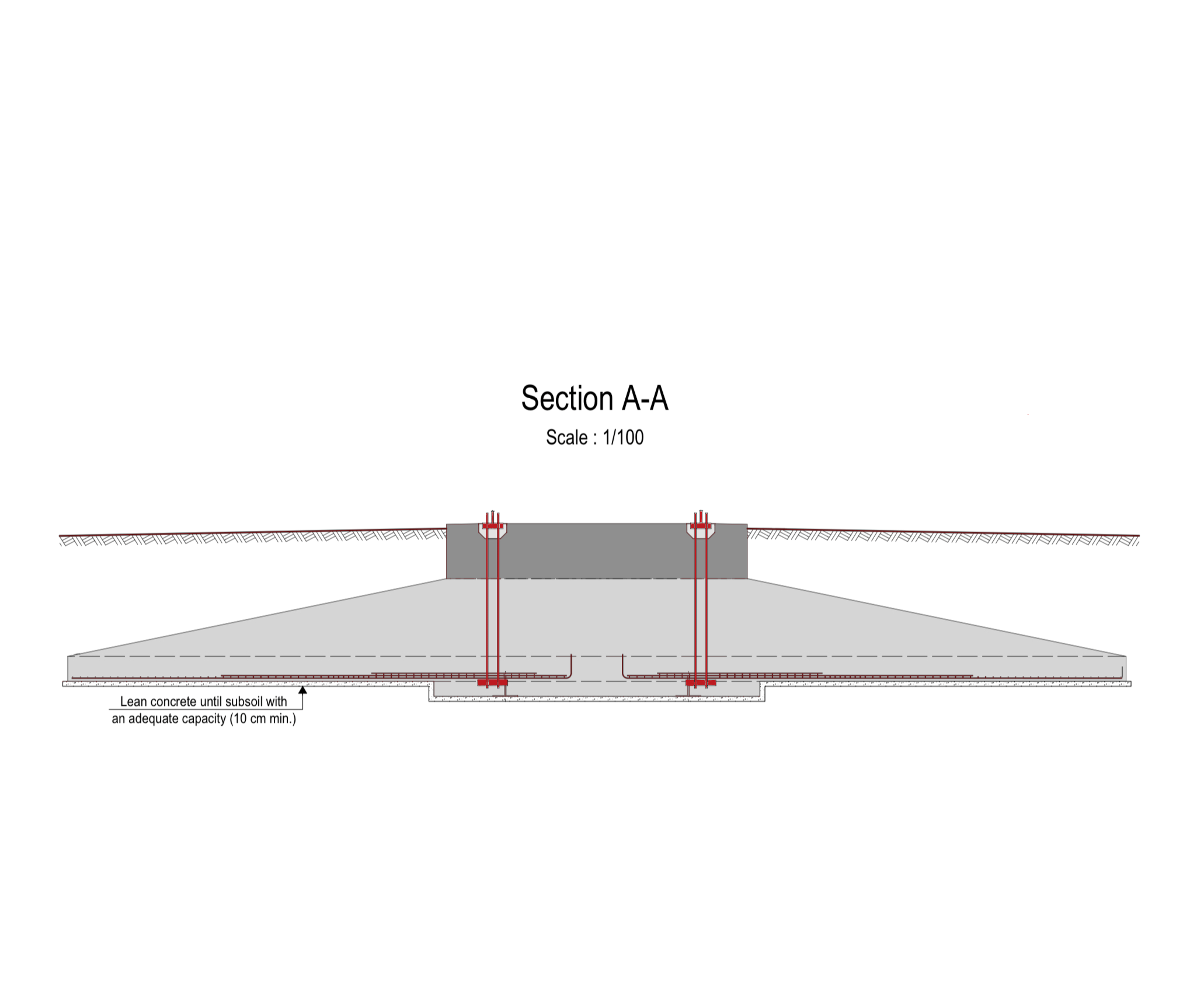

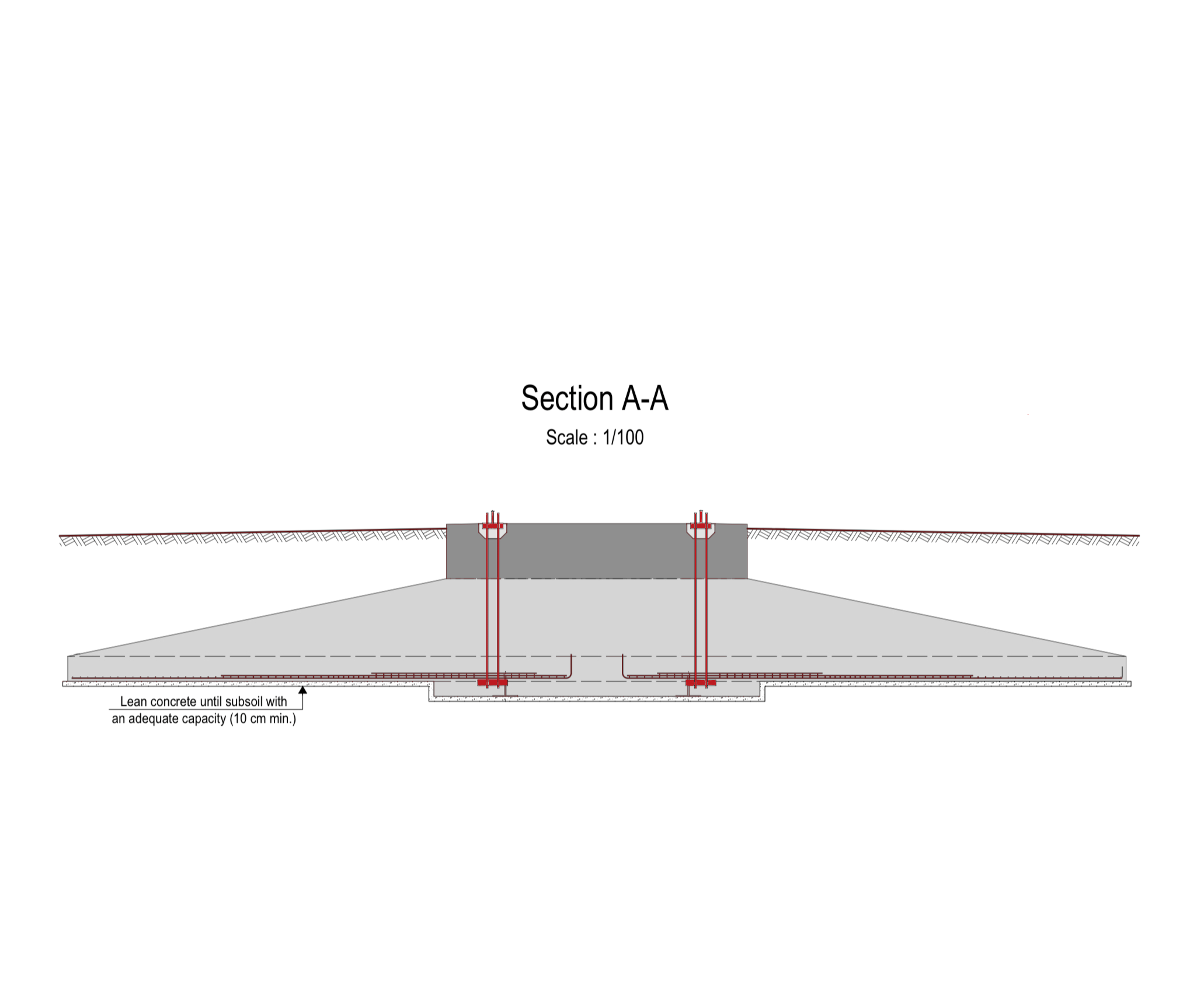

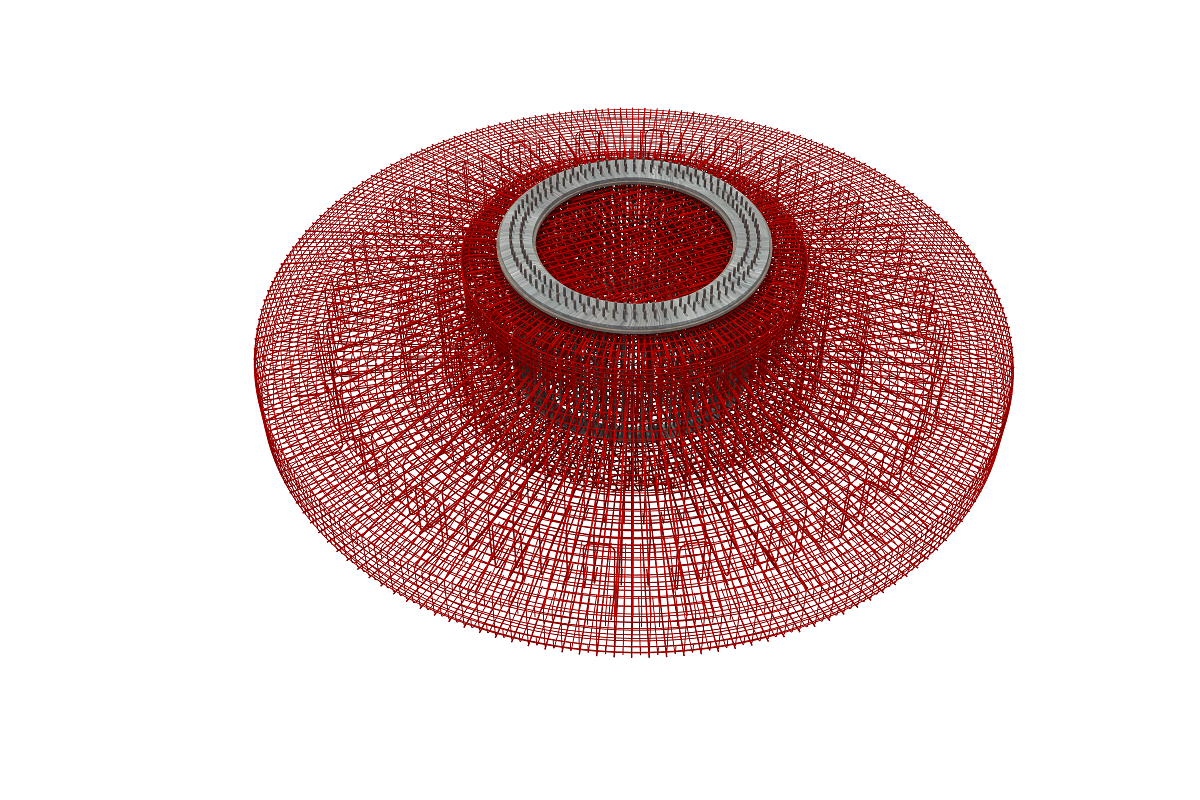

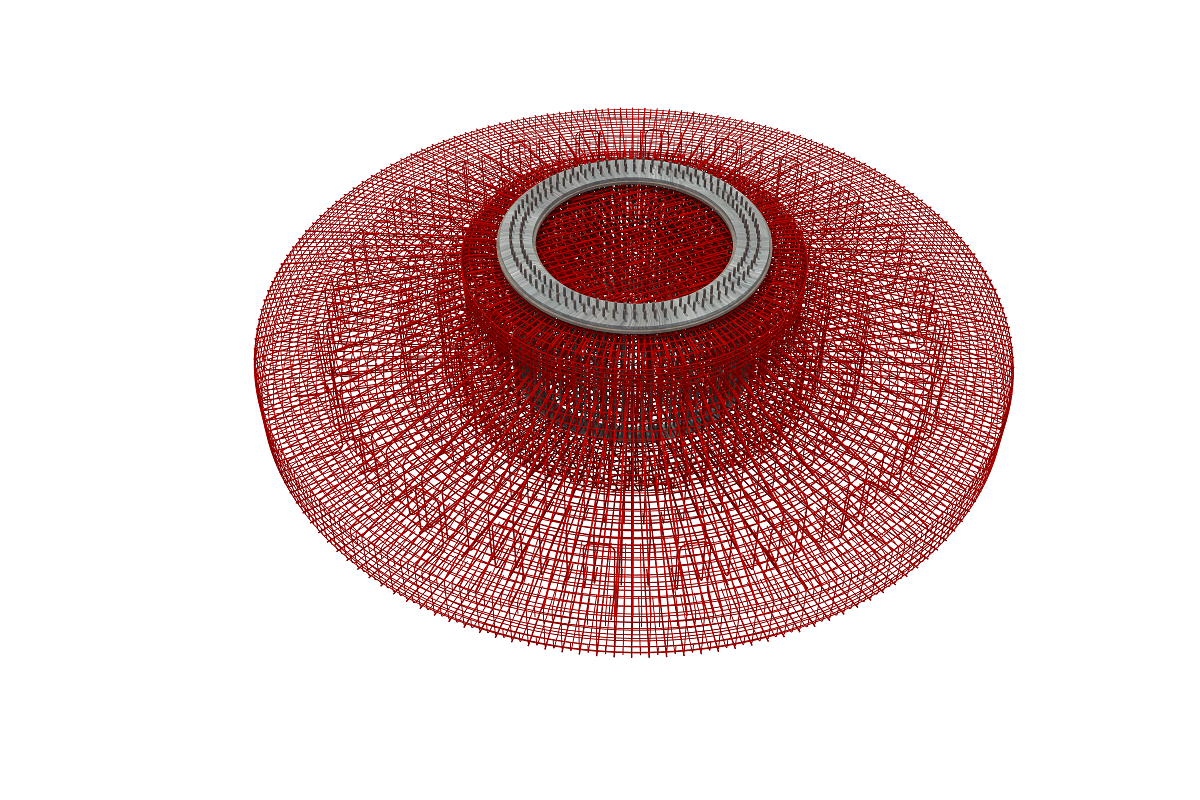

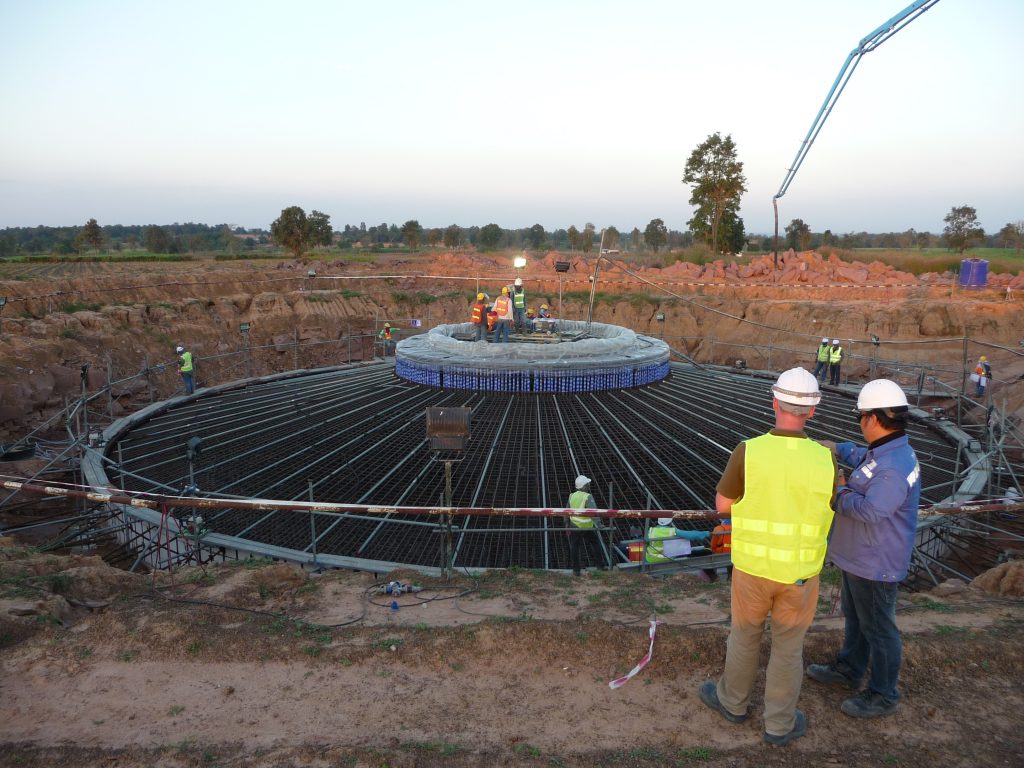

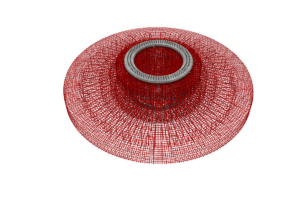

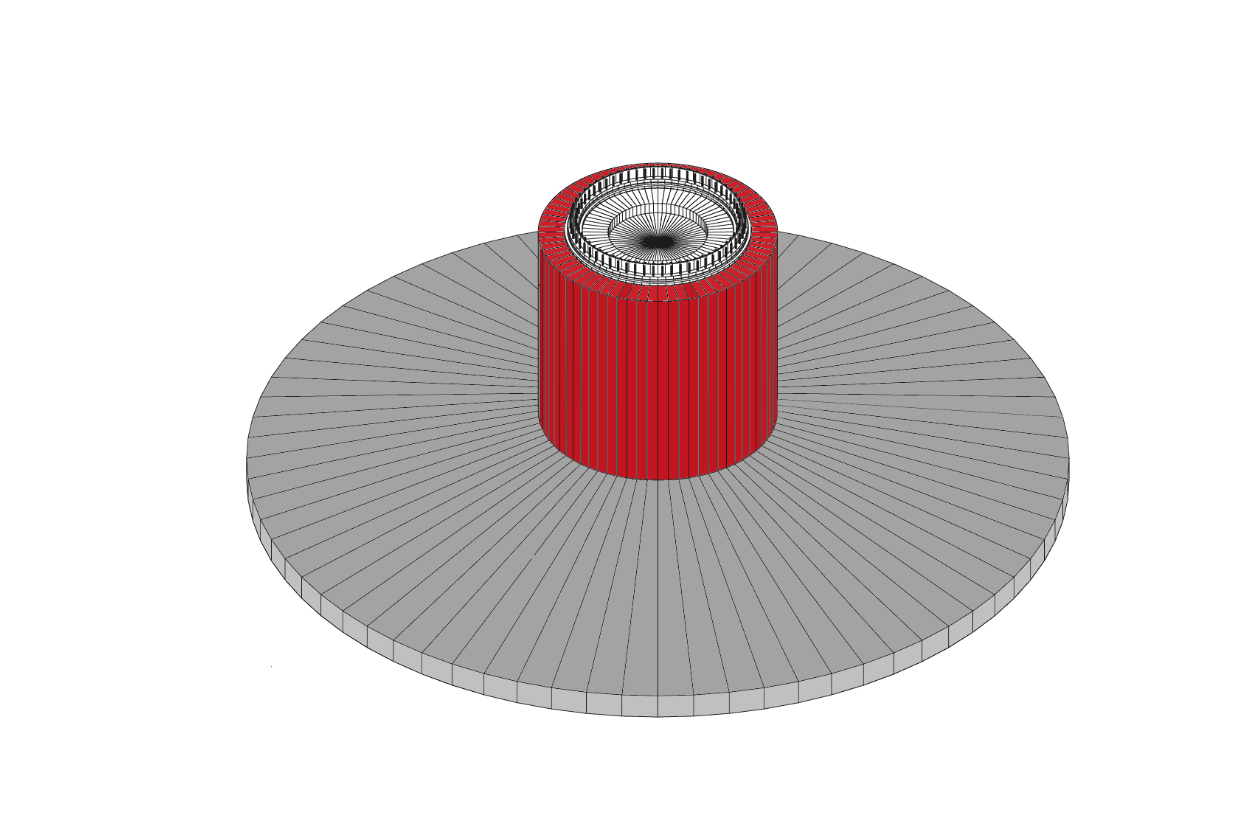

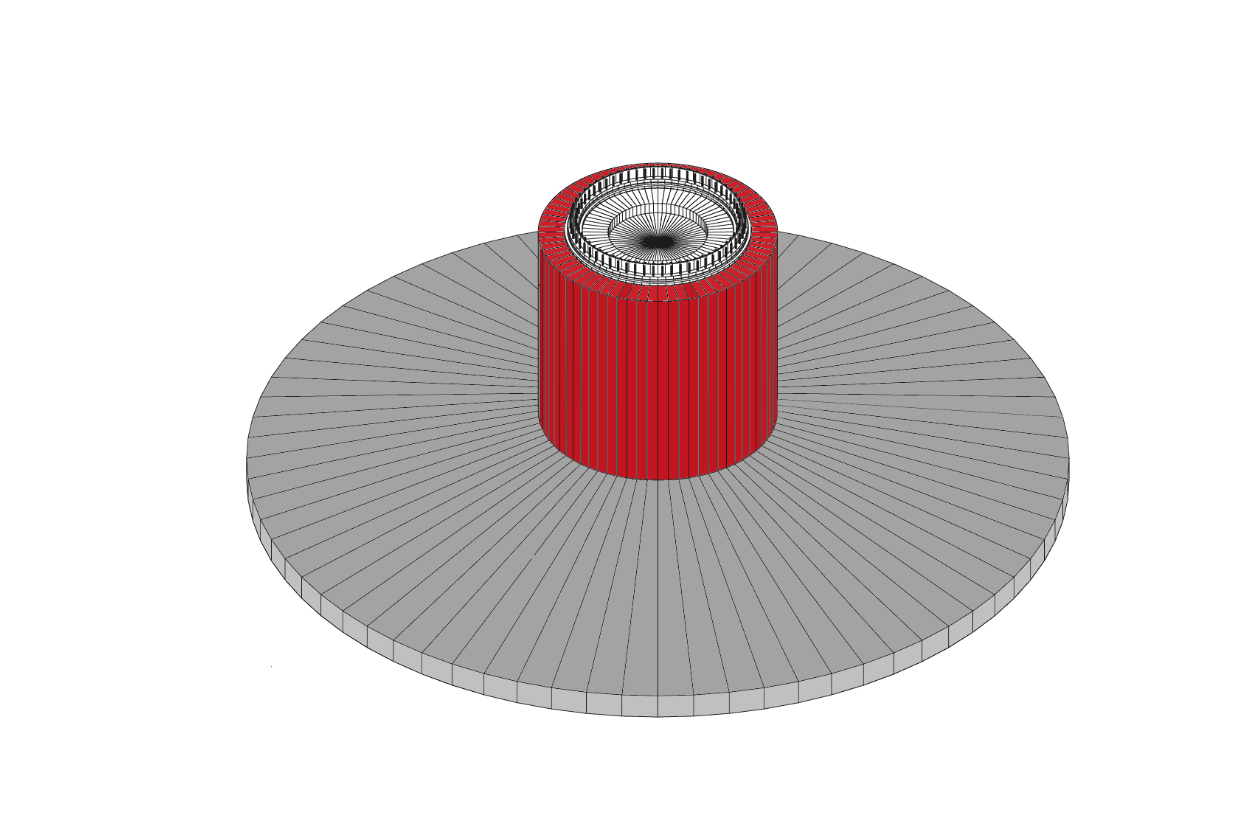

Developed by CTE Wind’s engineering team, the SOFT-SPOT™ solution is implemented in various countries around the world. This foundation design optimizes the bill of quantities as it saves concrete and reinforcement by reducing the foundation diameter. It is easy to be built as it does not change the construction of the gravity foundation.

CTE Wind has already implemented the SOFT-SPOT™ foundation solution at several hundreds projects around the world : Brazil, France, Lithuania, Indonesia, Mexico, Netherland, Russia, Serbia, Sweden and Thailand to name a few. Based on this real world experience, we have achieved concrete volume savings of up to 15% and reinforcing steel weight savings ranging from 2 to 5%. In cases with tight limits of disturbance, the reduction in foundation diameter can be more valuable than the savings in materials. The smaller diameter translates into reductions in disturbed area as well as in excavation time and volumes.

CTE WIND Civil Engineering presents to the market a new foundation system for wind turbines, a WTG shallow gravity foundation with SOFT-SPOT™ . Through placing a layer of soft material below the central part of the foundation, the slab will effectively act as a ring foundation with respect to soil-structure interaction. The bearing pressure of the WTG is concentrated at the annular contact surface closer to the edge of the slab. This increases the lever arm of the stabilizing moment. Therefore, the foundation diameter can be reduced in comparison to a standard foundation solution.

The SOFT-SPOT™ solution is offered to our clients as cost-saving option. Starting in the early estimating stages, we offer preliminary bills of quantities with and without the SOFT-SPOT™ option. If the SOFT-SPOT™ option is selected, we include it in our design drawings and specifications. During construction, we review shop drawings and perform site visits to make sure that design intent has been captured in the field.

Thanks to the SOFT-SPOT™ intelligent design, less excavation work is needed. This reduces the machine costs. A major point is that no additional training of site workers is required for the construction of the soft layer. The construction is very easy and the material for the soft layer can be purchased at low cost all over the world. Or as CTE Wind’s client H4a Windenergie B.V pointed out: It is simply the most economical foundation you can choose.

Please contact us if you are interested in knowing more about CTE Wind’s SOFT-SPOT™

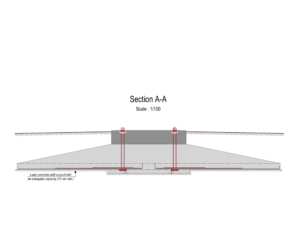

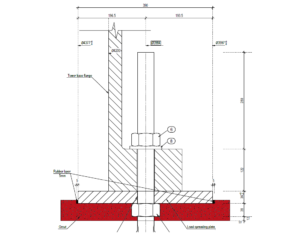

CTE Wind USA, Inc. offers The CTE-Sandwich™ as an engineering and engineering design service for the custom design of wind turbine foundations. In The CTE-Sandwich™ arrangement, the bottom mat reinforcement is run above the embedment ring sandwiching the entire foundation between two steel rings: the embedment ring and the tower base flange.

Engineers have approached the design of the pedestal/slab connection in a gravity base foundation differently in different parts of the world. In North America, vertical or “Omega” reinforcement bars are the commonly adopted mechanism for securing the pedestal to the base slab. However, vertical or Omega bars present construction challenges when they add to reinforcement congestion at a critical part of the foundation or clash with conduits. Reinforcement clashes are also unavoidable when these bars have to go through the bottom mat reinforcement layer, especially for an orthogonal bottom reinforcement layout.

At CTE Wind USA, we offer the vertical or Omega bar solution that North American contractors are familiar with. However, we also entice them with a “delicious” alternative: The CTE-Sandwich™. In this arrangement, bottom mat reinforcement is run above the embedment ring placing the sandwich goodies (the foundation slab) between two buns (the embedment ring and the tower base flange). Think of the concrete as the meat and the bottom and top reinforcement as the vegetables. Keeping the sandwich goodies between the buns should keep the sandwich together…. All one would need is a good grip!

Aside from the analogy, The CTE-Sandwich™ results in a positive connection between the pedestal and the base slab and practically eliminates the need for vertical or Omega bars, thereby saving on steel quantities. Construction is also more streamlined, particularly for round foundations with radial top and bottom reinforcement. We also note great synergy between The The CTE-Sandwich™ and the SOFT-SPOT™ … These technologies work hand in glove to achieve the best outcomes in terms of optimizing quantities and improving constructability without compromising reliability!

Please contact us if you are interested in knowing more about The CTE-Sandwich™/SOFT-SPOT™ combo

The anchor cage design solution allows to optimize the foundation design and so the bill of concrete and steel quantities.

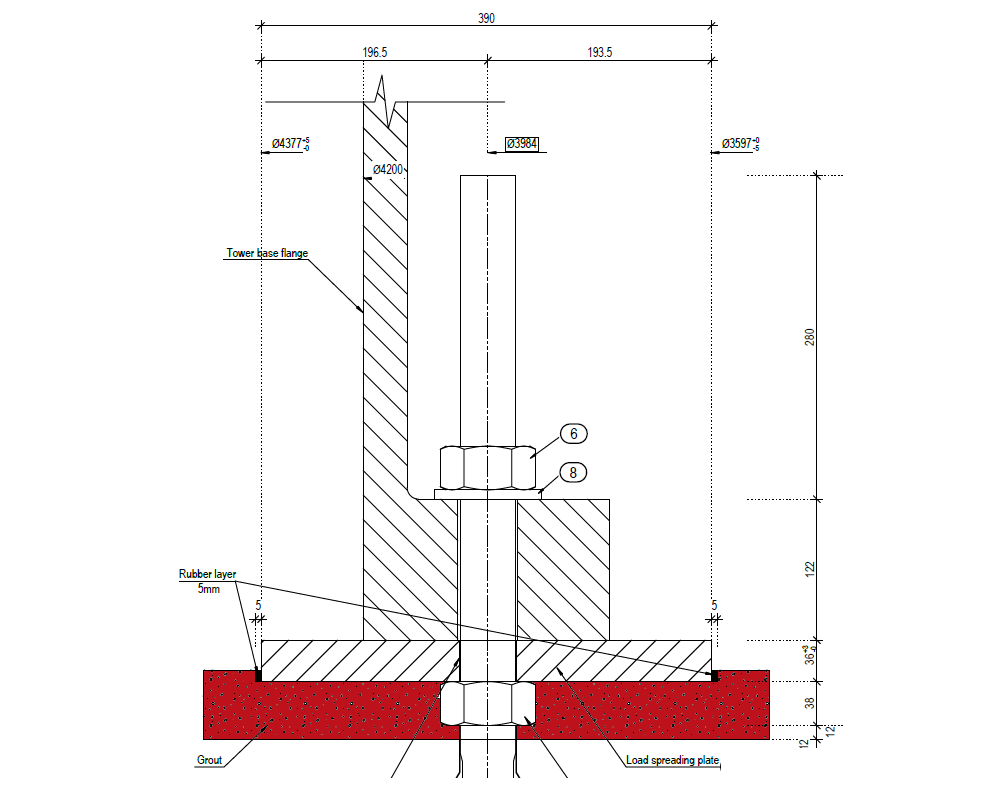

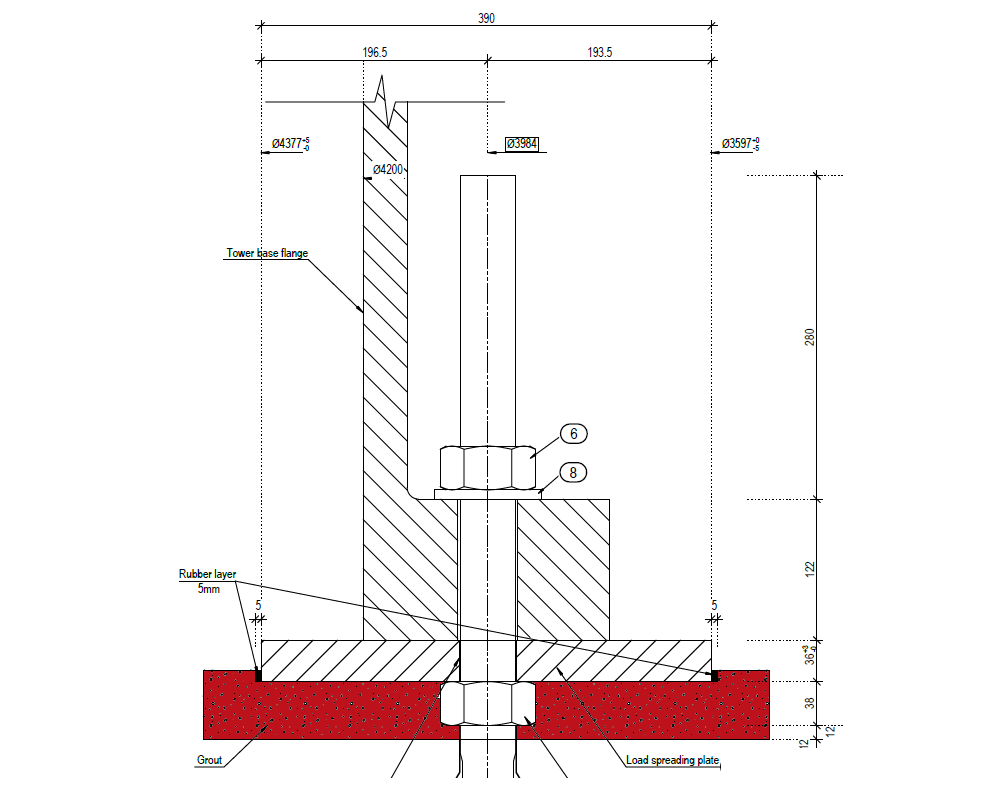

In the US a mandatory service from the structural engineer, in Europe delivered by the OEM: the anchor cage design. A well-designed anchor cage, or bolt cage, optimizes the bill of quantities of a wind turbine foundation (WTG) foundation. This special knowhow – or in French «savoir-faire» – of inhouse cage design leads CTE Wind to sophisticated foundation solutions such as the rock adaptor or the high plinth. The last mentioned helps to reach higher hub heights thanks his high pedestal. The tower stands 3 to 6 meters above the «ground level». The solution ideally provides also the design of the anchor cage. CTE Wind’s engineering team develops the cage and determines the bolt length, the pre-stress loads, the steel quality and all other necessary parameters.

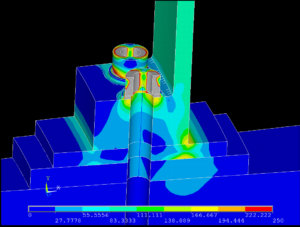

CTE Wind uses for the design of anchor cages the finite element method (FEM) which allows to analyze the behavior of structures with complex geometries and strong loads. The picture above shows the stress distribution in a tower base flange connection to the cage. Models like that help to verify structural integrity. FEM in combination with CTE Winds «savoir-faire», allows – in case something goes wrong during construction phase – to find repair solutions. Several clients have saved money and time thanks to CTE Wind’s pathology experience and FEM-skills.

Please contact us if you are interested in knowing more about CTE Wind’s anchor cage design.

The rock anchor is a complex but efficient foundation solution. It reduces the volume of concrete and steel tonnage by using rock as the principal foundation. The rock anchor is highly cost efficient, feasible and has proven to be very reliable in many projects.

This solution uses the rock masses as a WTG foundation. Basically, the tower rests on the top of a small reinforced concrete block.

Two approaches are available:

The anchors counteract uplift forces acting on foundations and post-tension the concrete structures against the rock. The anchors are often about several meters long.

Wind park owner are able to take advantage of the earth crust instead of building a gravity foundation for their wind turbines. The costs for the reinforced concrete and the construction work can be saved.

Soil anchors and rock anchors provide a high load capacity and the bond length can simply be increased to accommodate the required load. Anchors do not involve large excavation areas as required by alternative methods and are a particularly attractive option when space is limited and when low impact or the environment is a priority.

This solution is specially challenging as the engineers have to adapt the foundation, with an interface, between the towers and the rock anchors. Not to forget the special design work of these anchors that needs to be done.

Rock anchors are made of high tensile steel, and typically they are anchored in sound bedrock by means of high strength grouting. Ducts are placed in the concrete and holes will be drilled into the rock for post-tensioning application.

The anchors may be bolts or cables. For most applications the rock anchors are tensioned to a force higher than what is necessary to resist the foundation uplift force. They are eventually grouted on a part of their length to allow for a certain free tensioning length.

Please contact us if you are interested in knowing more about CTE Wind’s rock-anchor solution

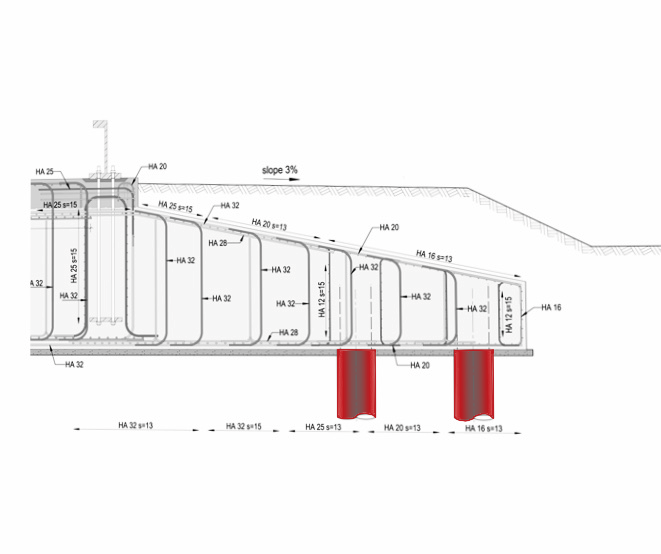

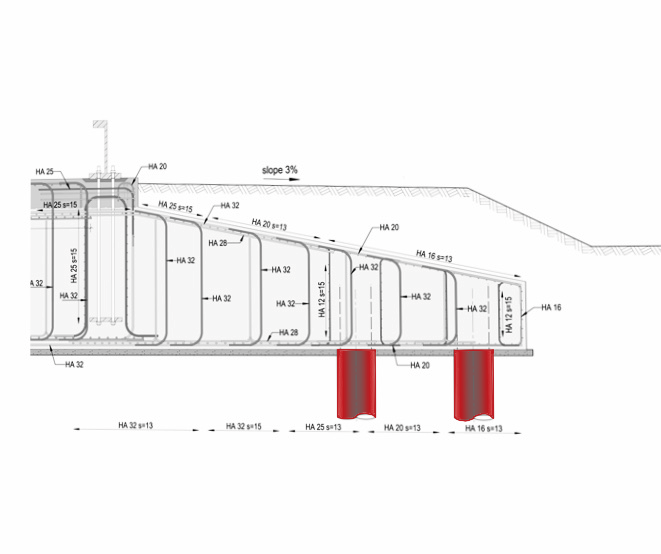

The design of this solution consists of a slab foundation for a steel or a concrete tower. It is the most common form of a foundation for wind turbines but yet remains a complex structure.

Wind Turbine Generators (WTGs) are becoming more and more powerful and the hub heights are increasing by the day. As a result, the concrete volume can reach these days to more than 1000 cubic meters per foundation.

CTE Wind has optimized the bill of quantities massively over the last decades. And still is continuing by means of research to work on effective improvements with the main objective of delivering resource-saving but reliable design solutions.

The significant advantages of CTE Wind’s gravity foundation are:

CTE Wind continuously improves this standard solution. On one side by taking into account the developments of the turbine manufacturers (size and performance) and on the other hand through close cooperation in research and developments projects (Tower manufacturer, universities, standardization bodies etc.). The major purpose is to cut down the minimal concrete resistance class and to reduce the required amount of steel and concrete. Also improvements trough non-linear calculations.

CTE Wind adapts the gravity foundation to the existing soil conditions. Thus several variants of this standard slab solution exists. Furthermore it can be combined with other CTE Wind design solutions, such as the SOFT-SPOT®. CTE Wind’s experienced geotechnical and structural engineers support and advise our customers throughout the project.

Please contact us if you are interested in knowing more about CTE Wind’s gravity solution

Pile foundation transfer the load coming from the wind turbine foundation to the lower-lying ground thereby providing overall support to the structure. A pile foundation solution takes into account any type of piles (driven, precast, etc.).

A pile is basically a long cylinder or prism of reinforced concrete or a tube of steel that is placed in the ground to transfer the loads coming from top structure by friction or cap resistance.

Pile foundations are used in wind parks where the soil cannot bear the compression or tensile loads applied by the wind turbine.

The piles have to carry concentrated loads and are subject to fatigue loads, too. That is why piles must be designed carefully by study the soil reports drilling logs.

Some geotechnical experience is a must to be able to understand and interpret correctly!

Every pile has an area of influence in the ground around it which can also vary from one soil layer to the next.

Piles are long, slender columns. They can be determined as single elements but also as pile groups.

Once their dimensions vary under the same foundation cap – length or diameter – their stiffness will also change and then the design becomes a new dimension due to possible differential settlements.

A pile reinforcement drawing will be prepared.

In our current projects, piles length was found from 10 m to 70 m.

Please contact us if you are interested in knowing more about CTE Wind’s pile foundation.

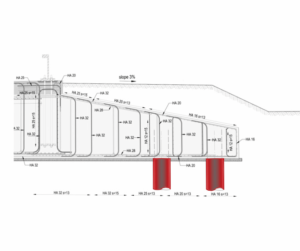

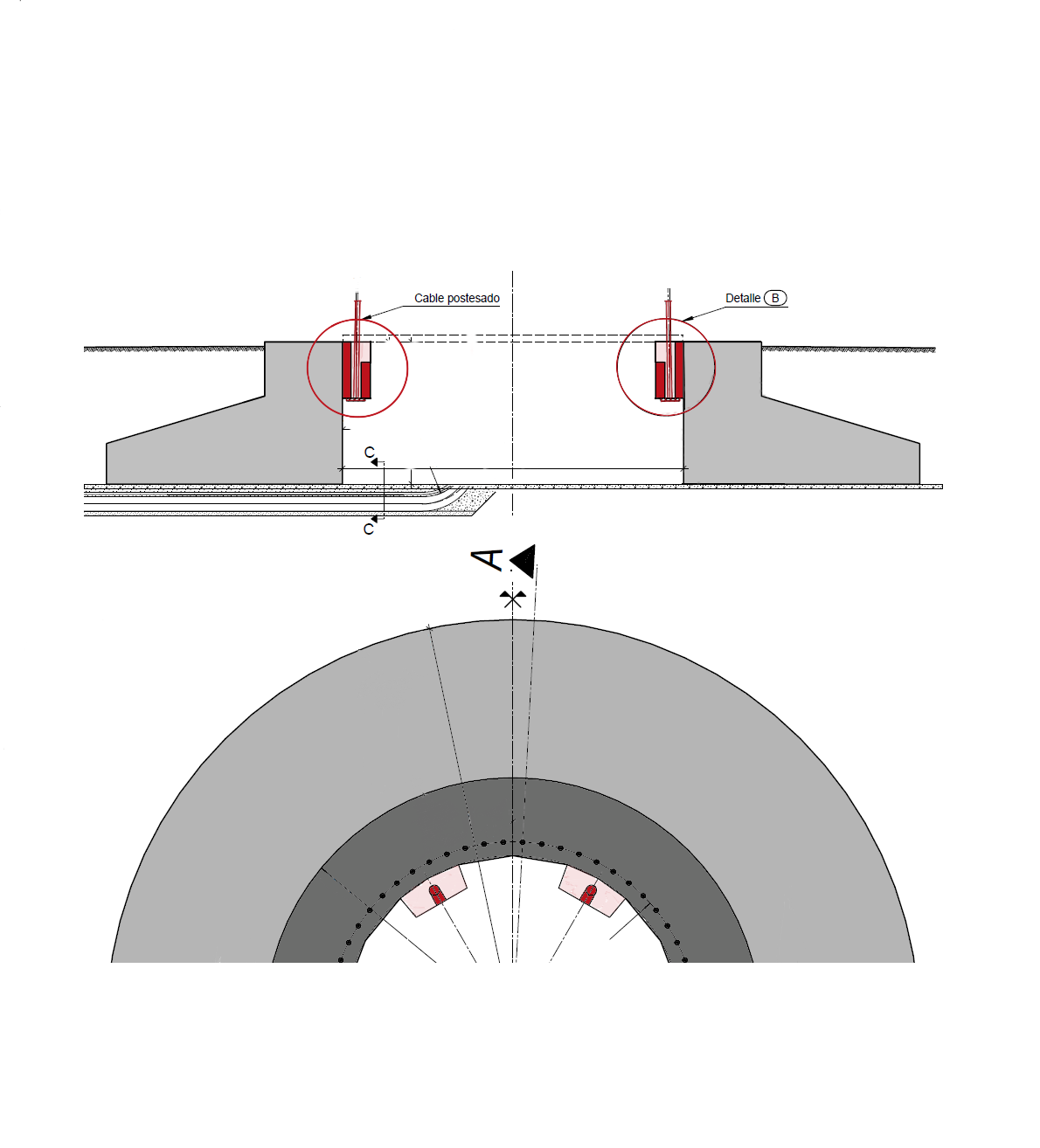

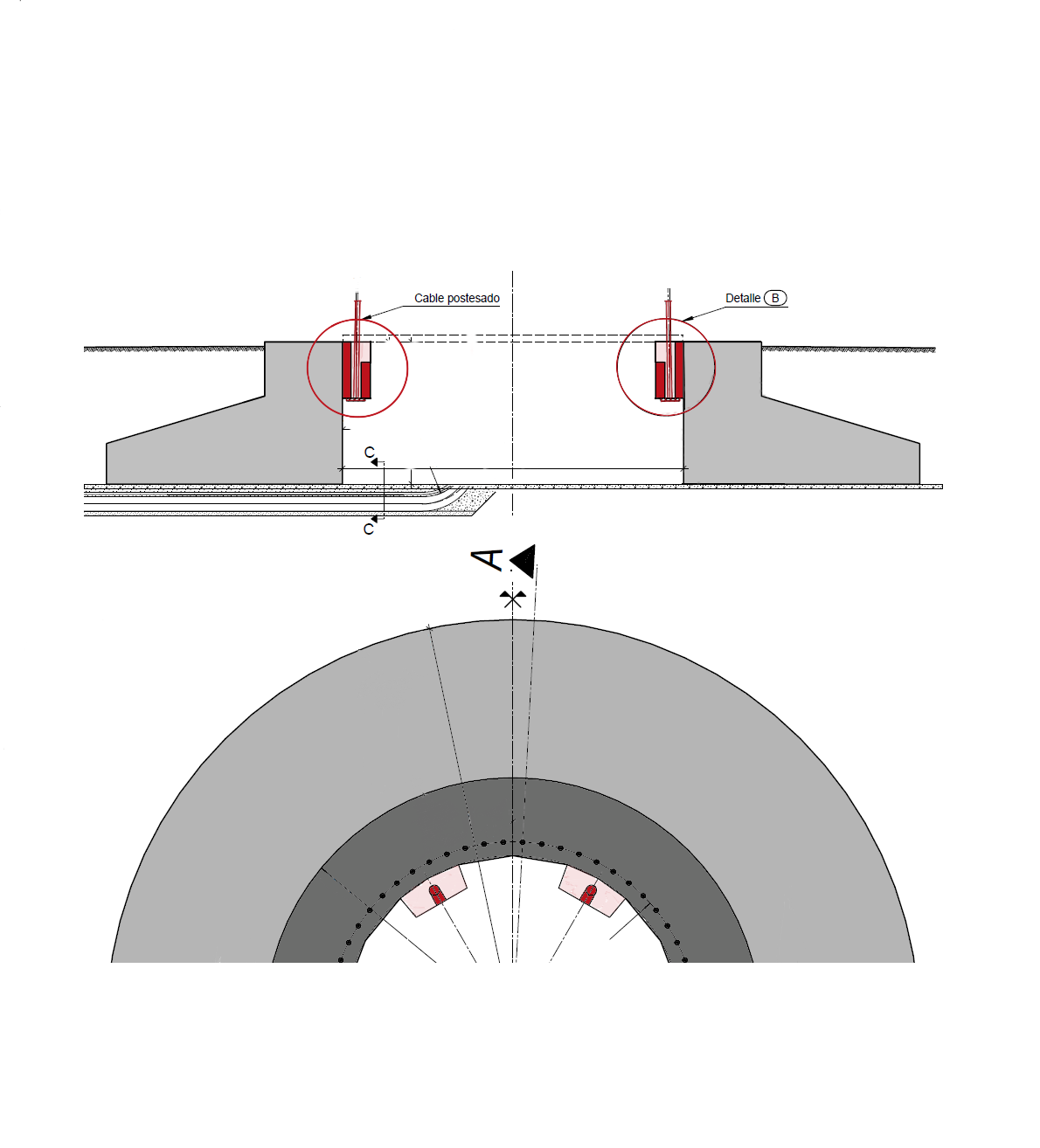

The Hollow Foundation Solution allows for anchoring of the concrete tower to the foundation using pre-stressing or post-tensioning cables.

While there are variants where the concrete tower sits directly on a classic slab foundation, the most common foundation scenario features a cellar where cables are anchored and cable tensioning tools are placed.

Reinforcement design for the hollow foundation solution is also substantially different from that of standard gravity foundations. Besides the customized interior formwork, special attention has to be paid to the the design of the anchoring bulkheads where concentrated loads are applied to the concrete in very limited spaces.

The lower surface of the foundation acts as a bearing ring while the higher weight of the concete tower helps to stabilize the entire structure. The lid overing of the foundation cellar requires special attention to prevent water ingress.

Please contact us if you are interested in knowing more about CTE Wind’s hollow foundation solutions.

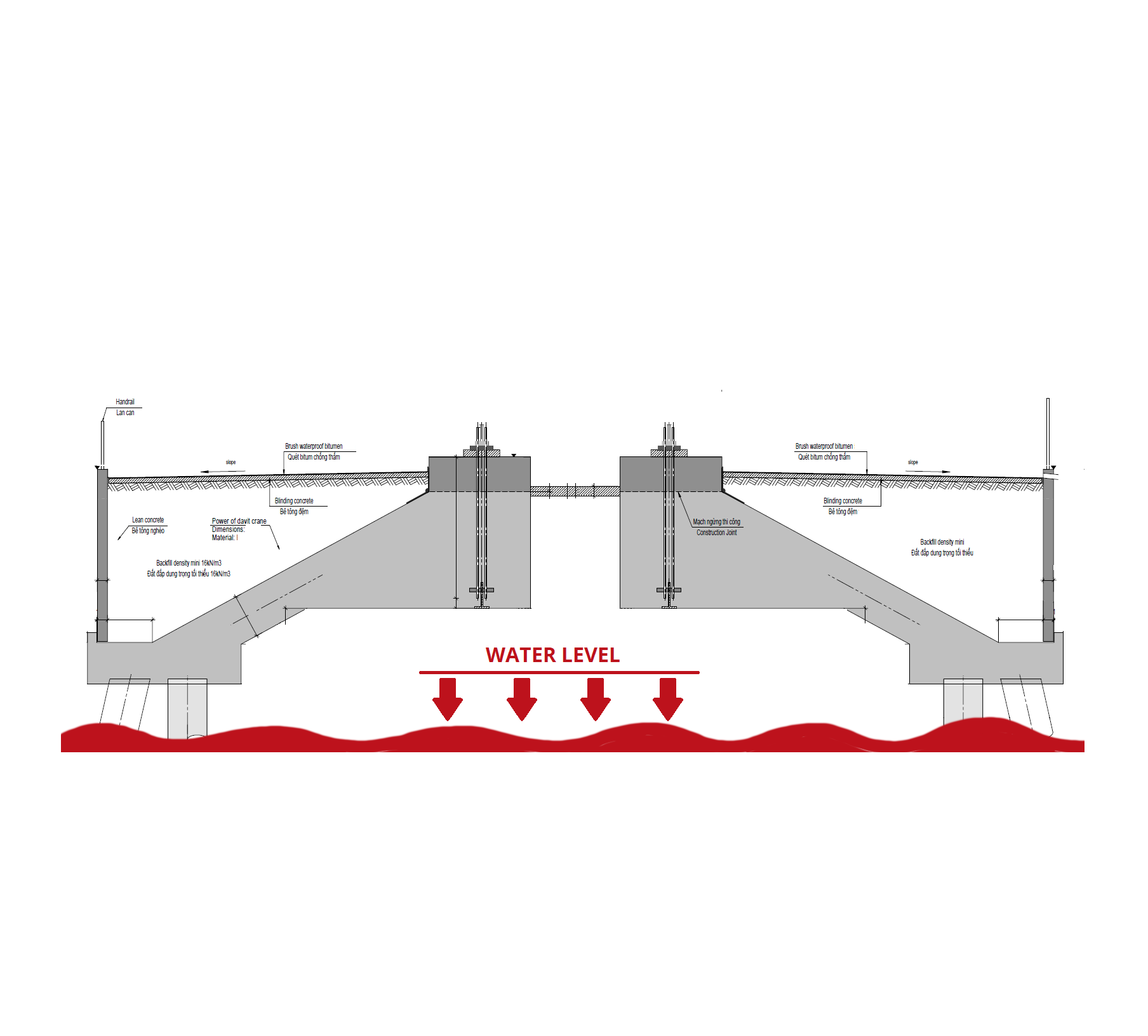

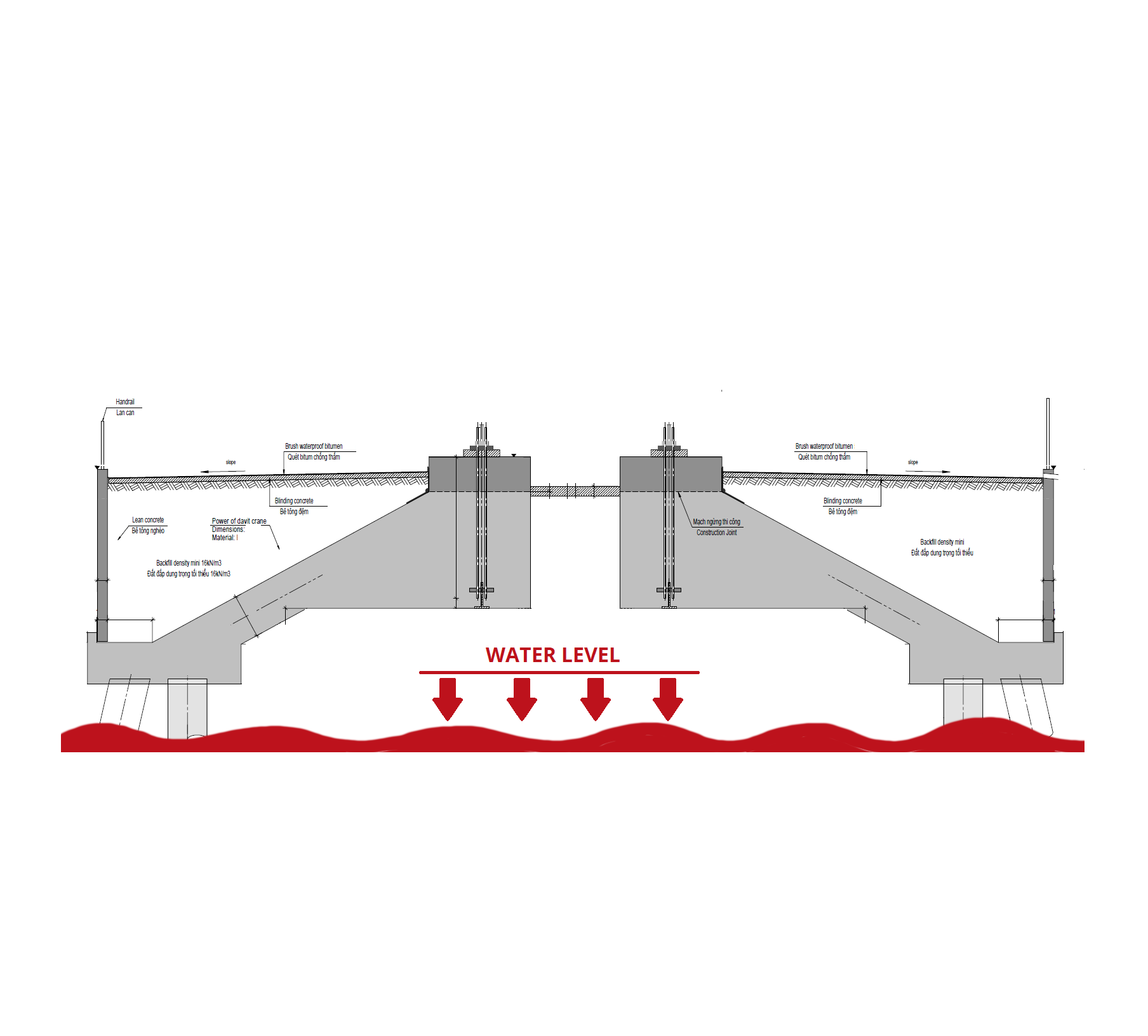

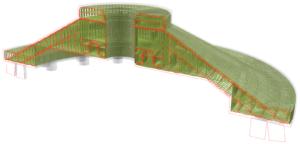

The nearshore foundation is a proven solution in intertidal regions. During the low tide the foundation is exposed to the air and submerged in seawater at high tide. On sandy beaches with muddy underground the foundations can require piles up to 70 meters length.

CTE Wind’s special solution allows to save about 30 percent of the construction costs due to the astonishing design and compared to similar projects from third parties.

The solution provides a circular, cone like foundation on top of piles which are designed in-house. To tackle the challenging environmental criteria for geotechnics, tides, waves and ship movements close to the platforms, the patented foundation takes also the feasibility into account

CTV, the Asiaese office of CTE Wind, has already designed five wind farm projects with its patented solution.

As nearshore is the area from the swash zone to the position marking the start of the offshore zone defined. Typically, the water depths in nearshore areas are up to of 20 meters. In intertidal zones the water level can change massively between 5 – 15 meters during high and low tide. It is located on marine coastlines, including rocky shores and sandy beaches.

Please contact us if you are interested in knowing more about CTE Wind’s nearshore foundation.

High plinth / pedestal foundation allows to reach higher hub heights when the tower is too short.This allows to increase the productivity of the wind turbine.

The idea of this foundation is to reach higher hub height with a high pedestal. The tower stands 3 to 6 meters above the «ground level». The tower does not experience any modification and the construction of the foundation does not require bigger cranes.

Ideally, this solution is combined with a longer anchor cage so that pedestal and slab are well connected in order to avoid cracking.

CTE Wind’s engineering team can provide the design for the anchor cage and also prepare the detailed anchor cage drawing.

The high plinth foundation is already tested and implemented in multiple projects in Europe and Latin America.

Wind velocity at higher altitudes can be higher than at the soil. That’s why it is more beneficial to put the turbine high in the sky where there is more energy to extract.

The high plinth solution allows with his higher hub heights to catch faster and more stable wind speeds. But no only. By increasing the hub heights the wind turbine is able to carry larger and longer turbine blades. Wich mean greater aerodynamic efficiency for the same machine by keeping the same tower lenght.

Please contact us if you are interested in knowing more about CTE Wind’s high plinth foundation.

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies. However you may visit Cookie Settings to provide a controlled consent.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| PHPSESSID | session | This cookie is native to PHP applications. The cookie is used to store and identify a users' unique session ID for the purpose of managing user session on the website. The cookie is a session cookies and is deleted when all the browser windows are closed. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by Google. In addition to certain standard Google cookies, reCAPTCHA sets a necessary cookie (_GRECAPTCHA) when executed for the purpose of providing its risk analysis. |

| Cookie | Duration | Description |

|---|---|---|

| pll_language | 1 year | This cookie is set by Polylang plugin for WordPress powered websites. The cookie stores the language code of the last browsed page. |

| Cookie | Duration | Description |

|---|---|---|

| _gat | 1 minute | This cookies is installed by Google Universal Analytics to throttle the request rate to limit the colllection of data on high traffic sites. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assign a randomly generated number to identify unique visitors. |

| _gat_gtag_UA_151427895_1 | 1 minute | This cookie is set by Google Tag Manager and is used to throttle request rate and to store and track conversions. |

| _gid | 1 day | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the website is doing. The data collected including the number visitors, the source where they have come from, and the pages visted in an anonymous form. |